AI-Powered Cobot Application Development

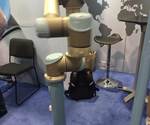

Universal Robots’ AI Accelerator hardware and software tool kit enables development of AI-powered cobot applications.

Universal Robots (UR) says its AI Accelerator will enable AI-powered cobot application innovations. The company describes its UR AI Accelerator as a ready-to-use hardware and software tool kit for developing AI-powered commercial and research cobot applications.

Powered by NVIDIA Isaac accelerated libraries and AI models, the tool kit applies AI capabilities to UR’s PolyScope X software platform and runs on the NVIDIA Jetson AGX Orin system-on-module. The tool kit also includes the Orbbec Gemini 335Lg 3D camera.

Universal Robots (UR) AI Accelerator utilizes NVIDIA Isaac accelerated libraries and AI models.

Source: Universal Robots

Built-in demo programs enable pose estimation, tracking, object detection, path planning, image classification, quality inspection, state detection and more. Enabled by PolyScope X, the UR AI Accelerator also gives developers the freedom to choose exactly which tool sets, programming languages and libraries they want to use, as well as the flexibility to create their own programs.

In a release, UR says users building programs on the new platform will be able decrease time to deployment. Also, the AI Accelerator is just the first to market of a series of AI-powered products and capabilities in UR’s pipeline, all of which are focused on making robotics more accessible.

The PolyScope X platform is available globally and can be used for cobot automation applications across industries. UR notes that with a small hardware upgrade, the software is compatible with UR’s e-Series cobots and the new-generation UR20 and UR30 cobots.

Related Content

-

'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.