Arburg Marks Anniversary with New Generation of Machines

The Hehl family company, which grew into Arburg, marks its centennial this year with a new generation of energy and resource efficient hybrid injection molding machines.

After teasing details about the machines in the midst of centennial celebrations, Arburg is offering more specifics on its 470 H hybrid injection molding machines available in Comfort, Premium and Ultimate variations, saying the series marks the start of a new generation of machines from company. Offering a clamping force of 110 tons and 18.5 in. between the tiebars, the Allround 470 H initially offers injection units with shot sizes of 3.7, 6.1 and 8.2 oz. There are three injection units apiece in the Comfort, Premium and Ultimate models, with the footprints for Comfort and Premium machines ranging from 160 in. by 64 in. up to 180 in. by 64 in., while the Ultimate goes from 166 in. by 64 in. up to 180 by 64 in. and offers faster injection speeds and injection flow.

Combining an electric clamping unit and hydraulic injection unit, the 470 H also utilizes a new oil-management concept wherein the oil flow of the hydraulic pump is split making it possible to drive an additional secondary axis at the same time. This advance contributes in part to an energy footprint that’s 50% smaller than a comparable hydraulic machine, according to Arburg, with the ability to save up to 12,000 kg/yr of CO2, depending on the application.

The new hybrid Allrounder 470 H injection molding machines are available in Comfort, Premium and Ultimate variations, with the latter providing faster injection speeds and greater injection flow.

Photo Credit: Arburg

In addition to maximizing energy usage, the new oil-management concept allows the machine to use roughly 35% less oil. Using waste heat from the machine to pre-heat the oil boosts efficiency further, as it does not flow back into the cooling water circuit as residual heat. Arburg notes that the 470 H’s required cooling water capacity is also between 50 and 70% lower, with a reduction in the dry cycle time of up to 33%.

Offering “Comfort”, “Premium” and “Ultimate” performance variants, the machines will feature various injection units and a wide range of options for customers who are looking for an energy-saving alternative to hydraulic machines, but also want their proven benefits, according to Arburg.

Oil Management

In addition to splitting the oil flow for simultaneous movements within the hydraulic system, Arburg has upgraded other aspects of oil management on the machines. These include an improved oil container, a differential pressure-enabled oil filter housing and predictive maintenance for both filter changes and oil-pump inspection. Under this system, the warning message for a dirty filter is issued when the level reaches 75% capacity, giving molder’s adequate time to secure and install a replacement. Further, by attaching the filter element to the removable cover with a handle and making the filter housing accessible on the operating side, the machine’s design has improved the ergonomics of filter management.

By separating hot, contaminated hydraulic oil from cold, clean hydraulic oil in the oil container, the energy and cooling water consumption are decreased while the the service life of the individual components, is increased, in some cases considerably, according to the company.

The the Allrounder 470 H Comfort and Premium machines utilize the previously proven Arburg servo hydraulic system (ASH), which has already been integrated into hydraulic and electric Allrounders. ASH uses a speed-controlled, water-cooled servomotor to continuously adjust the drive system to the actual power requirements, so that, for example, when the machine stops moving, the pump drive also stops and there are no idling losses. This can save up to 50% of the energy used, especially in processes with long cooling times. It also reduces the machine’s cooling requirements and noise levels.

A real-time Ethernet bus replaces the individual ribbon cables of the control modules, increasing service life, while hardware on and in the machine base has been completely reconfigured. The control manifold and hydraulic accumulator have been moved inside, leaving more space for peripheral equipment at the rear side of the 470 H Allrounder machines. The electrical, hydraulic and water media circuits have been separated, which simplifies assembly and service, with the hydraulic and water circuits located in the machine base, while the pneumatic and central lubrication systems are on the operating side.

The new Comfort and Premium Allrounder 470 H machines made their world premier as part of the celebratory events at Arburg’s headquarters in Lossburg in February 2023. These anniversary machines were also on display during the company’s Anniversary Days in March, and will be seen at shows all around the world in 2023.

Partnering with INEOS Styrolution

At Anniversary Days and at Fakuma 2023 (Oct. 17-21; Friedrichshafen, Germany), Arburg will partner with INEOS Styrolution on machine displays, utilizing grades from that company’s ECO line of materials, which offers mechanically recycled and partially biobased alternatives to conventional ABS. The first ECO grades successfully tested by Arburg on their latest generation of injection molding machines included Terluran ECO as well as NAS ECO.

The Terluran ECO, which serves as an alternative to conventional ABS, features grades with recycled content and biobased feedstocks. Mechanically-recycled grades contain up to 70% post-consumer recycled content, while the bio-attributed grades range all the way up to a completely bio-attributed resin: Terluran ECO B100. Featuring bio-attributed content from all three monomers — styrene monomer, butadiene and acrylonitrile — this resin’s B100 grade has a negative product carbon footprint.

NAS ECO is biobased SMMA material, offering transparency, low haze and good thermal and chemical resistance. The material provides a carbon footprint reduction of up to 99%. Like its conventional equivalent NAS, it is also suitable for food packaging solutions.

Arburg will process INEOS Styrolution’s ECO grades at Fakuma 2023 in support of its newest Allrounder line of injection molding machines.

Photo Credit: INEOS Styrolution

Related Content

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreU.S. Debut for Slimmed Down Electric Machine

NPE2024: Arburg’s debut of the 310-ton Allrounder 720 E Golden Electric extends the tonnage range of the electric series and marks the first global press premiere outside of Germany.

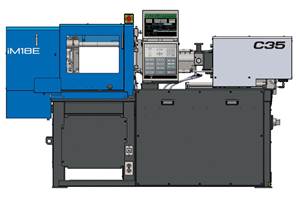

Read MoreCompact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreRead Next

Arburg Marks 100 Years with Celebratory Gathering, Machine Reveal

The family held injection molding machine maker celebrated its centennial with approximately 1200 guests from 32 countries and two “anniversary” hybrid presses.

Read MoreTechnology Days Returns

After a two-year hiatus, Arburg’s Technology Days event (June 22-25) returned in 2022 bring customers and plastics trade press from around the world to the company’s global headquarters in Lossburg, Germany.

Read MoreArburg Acquires Drive and Automation Company

The injection molding machine supplier has acquired its long-time development partner and supplier of electric drives, vertically integrating a key capacity.

Read More