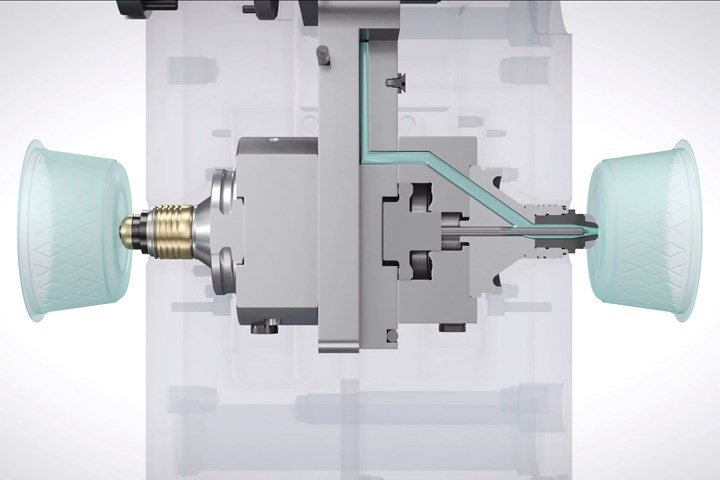

Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

Hot runner manufacturer Oerlikon HRSflow has designed a patent-pending compact stack mold for thin wall packaging applications. Designed to withstand high filling pressures for thin wall packaging applications, the system, which will be available soon, can be run on lower tonnage injection molding machines and is equipped with the company’s Xd nozzle series.

The design fits a maximum hot half plate thickness of 220 mm with a minimum distance between the gates on either side of the plate of 260 mm. In a video released with the announcement, Oerlikon HRSflow showed a four-drop design molding two 210-ml single-serving cups in recycled PP with a weight of 6.3g and a wall thickness of 0.3 mm on either side of the middle plate. What Oerlikon HRSflow calls a “mosaic” design on the cups’ walls was patented by moldmaker Collomb and imparts robustness to the container despite the thin walls.

The center plate of Oerlikon HRSflow’s stack mold fits a maximum hot-half plate thickness of 220 mm.

Photo Credit: Oerlikon HRSflow

Related Content

-

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

-

Consistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.