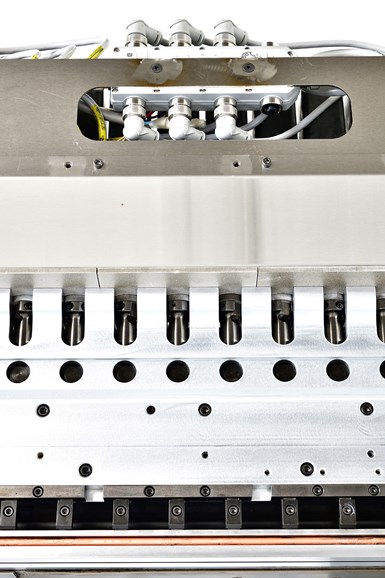

Die-Lip Adjustment System Relies on Motorized Actuators

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair.

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair. Called the EDI Prodigi System, it relies on motorized actuators to control the lip adjustment, and reportedly achieves saving tolerances four times faster than conventional thermal bolt systems.

For years, automated lip adjustment has been achieved using thermally actuated bolts. Thermal bolts are highly influenced by external factors, so thickness uniformity and consistency are sometimes hard to realize. Thermal bolts also typically require manual pre-tuning, so the process is not fully automated and hard to repeat consistently. Though effective and proven, it became clear that manufacturers needed a next level solution to meet their production needs.

“When we spoke with global customers, it was clear that they need more than excellent product uniformity — they need increased automation, says Scott Smith, global product managing director for Nordson’s EDI die business. “When skilled workers are hard to find, straightforward process control with less operator intervention is key to increasing a production line’s overall profitability. We knew there must be a better way.”

Photos: Nordson

After an initial concept was developed and specified, Nordson selected the Proflow family of actuators by Honeywell’s Process Solutions team to bring the new Prodigi die to market as quickly as possible. The installed actuators smoothly translate motor rotation into precise linear movement to locally open and close the lip. Accomplishing this away from the hot die, at a user interface, creates a process that is much faster, safer, and more energy efficient.

To evaluate the system, Nordson conducted a series of extrusion and fluid coating trials at its EDI Technology Center in Chippewa Falls, Wis., as well as a series of extrusion trials at the Fulton, N.Y., laboratory of Davis-Standard LLC.

“We achieved great results when we evaluated this new technology,” says Sam Iuliano, EDI chief technologist. "During our initial lip gap setting trials at Davis-Standard, we successfully closed the lip by 0.015 in. in only 35 sec. With a conventional automatic die, this procedure would involve using feeler gauges and iterative manual adjustments, which, in stark contrast, takes about 15 minutes to complete with reasonable accuracy."

The first round of tests at Davis-Standard, using multiple LyondellBasell resins and an NDC Technologies scanning system, also clearly showed how beneficial the Prodigi system is when it comes to both product uniformity and control speed.

Says Iuliano, "We set the desired lip gap, and when we started, the initial thickness variation was ±25%. Within a matter of 44 sec, the thickness variation decreased significantly, and after only three minutes from engaging Automatic Profile Control (APC), we had an almost perfect gauge over the complete length of the die. This compares to an average of 12 minutes to achieve the same tolerances using conventional thermal actuators. Customers will save significant time and be able to exactly repeat their production cycles. This will create much less scrap and add more productive time since final tolerances are achieved so quickly.”

“We have tested the Prodigi die system in comparison to current thermal bolt dies and the Prodigi system has proven to raise the performance bar an order of magnitude,” says Ricky Keller, v.p. market development with Davis-Standard’s Converting Systems line of business. I have witnessed step changes in APC over the past 40 years and the Prodigi system is definitely a large step forward for profile control of flat dies.”

“Throughout the trials, we were impressed by how fast the Prodigi™ die system is. We launched a saved lip profile recipe from a previous run and produced exceptionally flat film in only 30 seconds,” says Iuliano. “Davis-Standard stated that they usually need 8 min. to achieve the same tolerances from recipe launch with conventional thermal actuators.”

To gain a processor’s perspective, global packaging supplier Amcor was also invited to the development trials. “The performance of the Prodigi die, with its reproducibility and speed, will be a game changer for converters, reports Brent Martins, R&D Fellow with Amcor PLC. “We are always looking for tools to help reduce losses and improve our Overall Equipment Effectiveness as we move toward shorter runs. This new technology from Nordson will enable converters to achieve these goals safely and efficiently.”

The Prodigi system will also support fluid coating applications since its accuracy is so refined. “The coating line tests in our lab were extremely promising, and we will be able to support fluid coating customers with equally impressive results,” notes Iuliano.

Related Content

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More