Fakuma: BritAS Introduced New Melt Filter for Contaminated PET

The technology is suitable for post-consumer plastic waste, focused on PET as well as PET-similar materials.

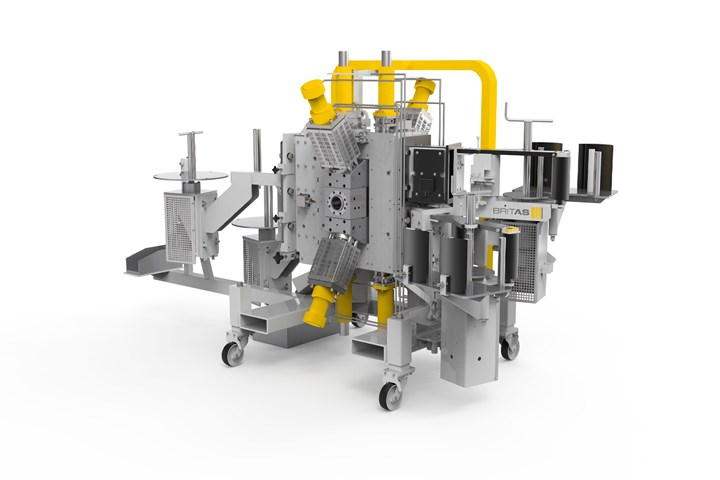

During Fakuma 2021, BritAS introduced its new ABMF PET-C, a melt filter for contaminated PET. The ABMF PET-C relies on the established BritAS basic technology and is equipped with special features while also being technically optimized. The filter is especially suitable for underwater as well as strand pelletizing, the company stated.

In order to filter contamination out of plastic waste effectively and efficiently, during each filter change, a clean screen mesh is inserted automatically and without production stop. Up to three screen belts can simultaneously be inserted, which reportedly allows an exact adjustment of different filter fineness. This keeps the quality of the re-granulate constantly high and the contamination is removed out of the machine with a very low melt loss. It features a filter fineness of up to 20 μm and melt loss of <1.0 %.

The technology is suitable for post-consumer plastic waste, focused on PET as well as PET-similar materials.

In combination, the filter mechanics and control offer a fully-automatic, practical operation in double-cavity mode, which does not require any temporary storage of the melt. During the screen movement, the extruder is not stopped and ensures process safety.

Besides the automatic operation of the double-cavity filter with high plastic throughput, the output is ensured by the use of screen belts with Dutch weave mesh. The operating costs of the melt filter is said to be reduced due to the optimized interior of the ABMF PET-C as well as the re-designed heating. The ABMF PET-C is available with a filter surface of 1.140 cm2 up to 3.200 m2 and a maximum output of 1030 kg/hr up to 4800 kg/hr.

The ABMF PET-C melt filter for contaminated PET.

Related Content

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Reversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

-

Building a Future With Sustainable Compounds

With roots in recycling, Star Plastics produces engineering thermoplastic compounds to meet performance and environmental goals.