Fakuma: Sumitomo (SHI) Demag Emphasizes All-Electrics and Permanent Machine Status Condition Monitoring

The company will feature three all-electric injection molding machines from its IntElect series, plus one from its El-Exis SP packaging range at the show in Friedrichshafen, Germany.

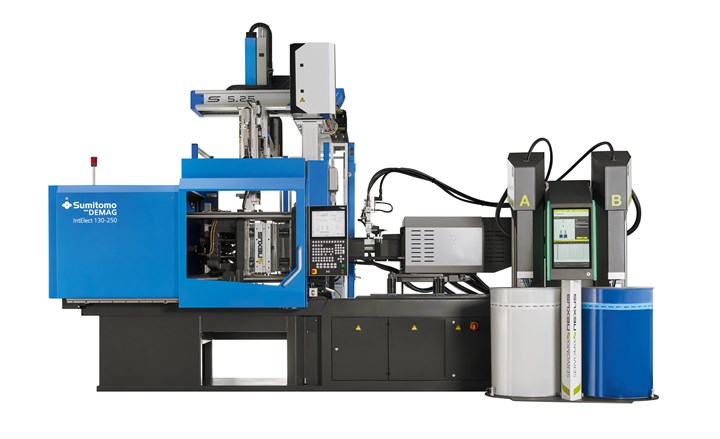

At Fakuma 2021, Sumitomo (SHI) Demag Plastics Machinery GmbH (Schwaig, Germany) will feature all-electric injection molding machines for LSR, IMD, medical and packaging applications. An IntElect 130/520-450 will include an LSR package, featuring a Servomix Z200 metering system from partner Nexus Elastomer Systems GmbH (Eberstalzell (Austria). Making its trade show debut, the LSR cell will mold a freeform automotive axial seal from a 16-cavity tool.

An IntElect 220/660-1100, equipped with a special plasticizing unit for running clear PC, will demonstrate IMD. Creating emblems for automotive exterior applications, the IMD decoration process involves back-injecting a second surface using a single image followed by contactless cleaning in a laminar flow box.

In a medical display, an IntElect S 100/460-250 with Waldorf Technik automation will mold caps for insulin syringes from a 16-cavity mold in a 6-sec cycle. A hybrid El-Exis SP 250 will showcase high-speed cup molding.

Permanent Condition Monitoring

Sumitomo will also use Fakuma to launch its permanent machine-status condition-monitoring system. The company says the technology can be used to determine the actual degree of wear and tear on machine components, enabling early detection and optimized maintenance planning. Using condition monitoring, processes can be analyzed directly on the machine.

In all, Sumitomo says three options will be highlighted. The first option reportedly helps to boost energy efficiency of all-electric machines. Another optimizes hydraulic machine oil parameters and maintains component quality. The third monitors control voltage across the entire injection molding machine series.

The company notes that the controller utilizes OPC/UA protocols, easing the machine’s integration and communication with other technologies in a plant. Additionally, Sumitomo will presents its advanced web-based software: myConnect. This platform gives customers direct access to a wide range of fully networked support service.

An IntElect 130/520-450 featuring an LSR package is making its trade show debut at Fakuma.

Related Content

-

Absolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

-

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

-

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.