Faster Top-Entry Model Among 19 Robots in Orlando

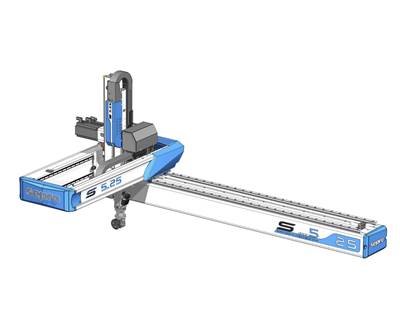

NPE2024: Sepro Group is introducing the newest S5-25 Speed robot, promising 63% faster acceleration, as one of 19 robots on display at its booth and partner booths at the show.

Sepro Group is introducing the newest S5-25 Speed top-entry robot at NPE2024, targeting fast-cycling injection molding applications. Upgrading to a more powerful servo motor and gear box on the horizontal (X) axis has resulted in 63% quicker acceleration and faster overall cycle times, as just some of the design improvements made since the robot’s introduction in 2018 at Fakuma. The top-entry configuration results in a smaller molding cell footprint compared to side-entry robots often used in high-speed applications. Sepro says ideal applications include simple packaging like flowerpots and thin-wall food containers and tubs.

The newest S5-25 Speed from Sepro Group, a top-entry robot solution for fast-cycling, injection-molding applications, will be on display for the first time at NPE2024. Source: Sepro

Now equipped with Sepro’s ECO Air feature, the S5-25 Speed has reduced compressed-air requirements for vacuum part gripping by as much as 85%. Instead of continuously using compressed air, the ECO Air system now monitors vacuum levels and only initiates vacuum generation when it’s required.

In one of three demonstration cells in the Sepro booth, the S5-25 Speed is paired with a 5X-25 robot to compare performance in side-by-side tests of speed and agility. Both units are based on the same mechanical platform but, while the S5-25 Speed is built for fast acceleration and short cycles, the 5X-25 is a 5-axis servo configuration with a 2-axis servo wrist, helping it excel at complex and precision part manipulation.

Another cell in the Sepro booth features three robots supporting a 125-ton Milacron Q Series injection molding machine. A Success 11X 5-axis Cartesian robot, a 6-axis 6X-170 articulated-arm unit and a cobot will handle not only part removal but also degating, laser marking, sorting (using 2D and 3D vision), label application and packing. All operations will be integrated by a Sepro Visual 3 control system.

The third demonstration in its booth features a 7X-55 robot designed to service larger molding machines up 2,500 tons. Here the robot will handle four different big parts: a rollout garbage can, a large-diameter pipe fitting, an automotive component and a heavy dumbbell. Quick-change end-of-arm tooling (EOAT) enables the robot to handle each part in succession, demonstrating how automation can support efficient short-run production of large components.

In addition to the six Sepro robots in its booth, a further 13 are operating on the stands of partner exhibitors, so that 19 Sepro robots in all will be running in Orlando, making Sepro’s NPE2024 presence its largest ever in terms of individual robots it has exhibited at a trade show.

Milacron is showing four private-labeled robots supplied by Sepro: a Success 33, two 6-axis articulated arm units will operate together in a Sepro-automated cell, and an S5-15 will operate on another Milacron machine. A fifth Milacron/Sepro robot, a servo-driven S5 Picker, can be seen on a Milacron press demonstrating gas-assist molding at the Bauer Compressors booth. Sepro will also supply end-of-arm tooling and guarding for all these installations.

Maruka is operating a total of four Sepro robots, with Cartesian units including a 5-axis 5X-15, a Success 11 and a Success 22, and a 6-axis articulated-arm 6X-70 also exhibited.

Elsewhere, Shibaura is operating a 5X-25 in axial configuration for clamp-end part deposition with Sepro-provided EOAT; Chen Hsong has a 5X-35 on a 700-ton press; and hot-runner system supplier Incoe is demonstrating a Success 11X on a 240-ton LS Mtron machine, with Sepro-provided conveyor and guarding.

Related Content

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreNew Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreRead Next

Sepro America Expands To Assemble Big Robots

Sepro America celebrated its 10th anniversary last week. showing off new space that will more than double its manufacturing area in Warrendale, Pa., including room for its first U.S. assembly of large robots.

Read MoreRobot & Cobot Makers Are Pairing Up

Sepro adds its Visual controls to UR collaborative robots.

Read MoreInjection Molding: Faster Robots & Cobots

Sepro introduces S5-25 Speed Cartesian model and Seprobot collaborative solution for standard robots.

Read More