High-Flow, Glass-Reinforced PEI for Small, More Sophisticated Electronic Components

SABIC’s two new Superflow Ultem grades address the trend of electronic component miniaturization.

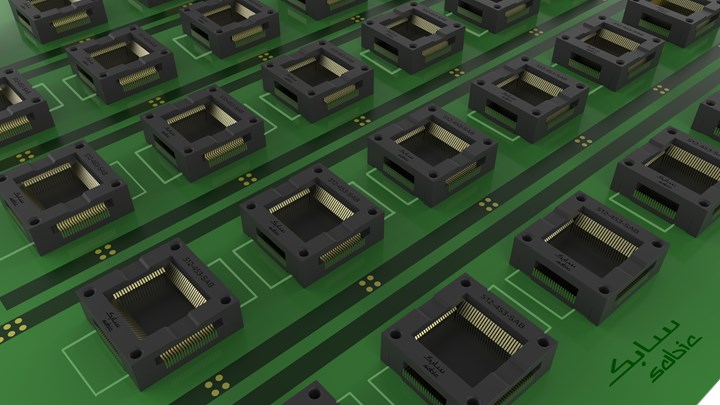

Two new grades of PEI that address the trend of electronic component miniaturization to enable smaller, lighter and more-sophisticated devices have been added to the Ultem product line from SABIC. Glass fiber-reinforced Superflow Ultem SF2250EPR and SF2270 resins reportedly feature exceptional flow properties for molding burn-in test sockets (BiTS) used to stress-test integrated circuit (IC) chips. They can also potentially be used to mold thin-wall, high-precision, miniaturized connectors. Their signature flow properties help meet the challenges of complete mold filling and easy release in ever-smaller components.

The two resins are positioned as very good alternatives to incumbent materials such as glass fiber-reinforced LCPs and PES resins. They have been shown to deliver greater weld line strength and mechanical performance than LCPs, and higher tensile strength and modulus, higher weld line strength and lower moisture absorption than PES resins. They can potentially replace high-flow, glass fiber-reinforced PES materials. Not only do these grades offer similar flow behavior compared to PES – avoiding the need for tool modification – they reportedly can deliver up to 20% higher strength and modulus, up to 9% percent lower density and lower moisture absorption.

Within the Ultem portfolio, the Superflow series provides the highest flow properties with up to five times longer flow length than standard glass fiber-reinforced Ultem resins. The high-flow performance can reduce the number of gates resulting in less breakage and higher production yields. Other benefits include lower melt temperature settings that can save energy and minimize outgassing, and accelerated cycle times for higher productivity.

Related Content

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Prices of Volume Resins Generally Flat or Lower

Exceptions in early March were PP and PS, which moved up solely due to feedstock constraints, along with slight upward movement in PVC and PET.

-

Prices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.