Improved Hot Runner Nozzle Gate Bushing

Thermoplay says the newest generation of its D-Bushing gate bushing features double sealing and high thermal performance, among other benefits.

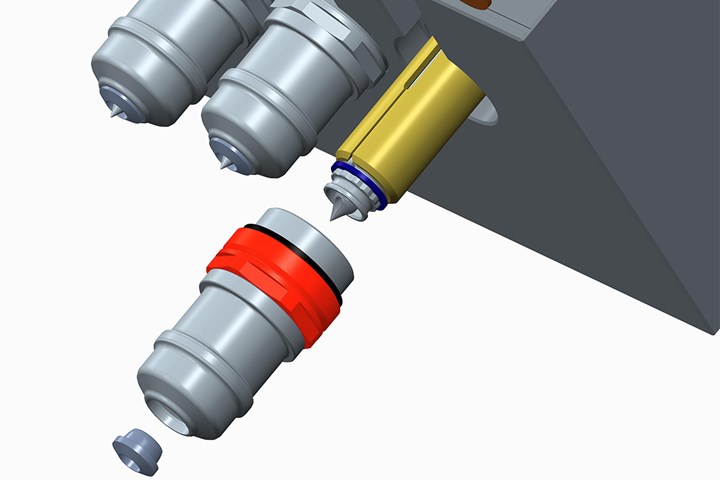

Thermoplay, part of the Molding Solutions business unit of Barnes Group, has introduced the newest generation of its D-Bushing gate bushing for preserving gate point quality and preventing plastics wear in hot runner nozzle components. The newest D Bushing specifically targets high-cavitation molds with frequent cavity-plate changes. Designed for Thermoplay’s new TF Nozzles, the D Bushing features a double sealing ring on the external diameter to protect from any resin leakage.

Thermoplay’s D Bushing can be fixed to both the nozzle plate and cavity plate by rotating the nut upward or downward.

In addition, the D-Bushing’s external sealing diameter both strengthens the nozzle while also helping preserve internal components from wear and accidental damage during assembly and disassembly operations. Thermoplay says by being close to the injection point, the sealing diameter allows easy and safe mounting and disassembling of the cavities as well as frequent mold changes. By creating an insulative barrier, the bushings also cut heat dissipation, saving energy consumption.

By using an external fixing ring, Thermoplay says assembly and disassembly of the D-Bushing is made easier and safer. The bushing can be fixed to both the nozzle plate and cavity plate by rotating the nut upward or downward. This also means the bushing does not increase the minimum pitch due to the nozzle diameter. The nut is fixed axially to the nozzle bushing. By turning it clockwise, the bushing is pushed toward the nozzle until there is coupling on the sealing diameter of the tip. When the default torque is applied, the bushing is fixed to the nozzle plate. By unscrewing the ring, the bushing is disassembled. The cable outlet in the middle of the nozzle body allows for replacement of the resitor, thermocouple, and tip without disassembling the injection system.

Thermoplay’s new D Bushing targets high-cavitiation molds with frequent cavity-plate changes.

Related Content

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.