Injection Molding Networking Software Adds Simulation Support

RJG’s Hub now supports Moldex 3D and Autodesk’s Moldflow/Insight injection molding simulation software.

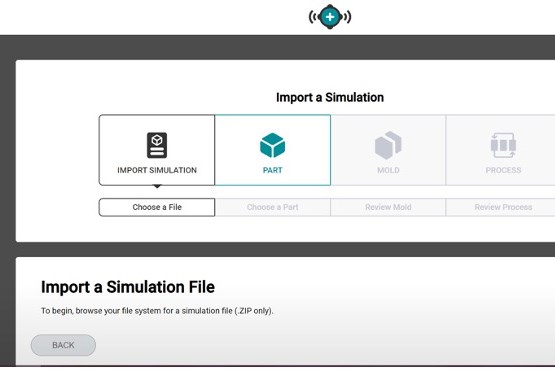

RJG’s (Traverse City, Mich.) injection molding networking software, The Hub, now offers a Simulation Support application. RJG says Simulation Support provides tools to launch a tool more effectively, applying Moldex 3D and Autodesk’s Moldflow/Insight injection molding simulation software.

The Hub connects CoPilot process control systems to a single interface, allowing users to access all plant information from anywhere, letting molders make data-driven decisions and improve operational efficiency.

The Hub for Simulation Support allows users to import simulation files into The Hub database and automatically generate a universal process sheet that they can convert to a machine specific setup sheet for any capable machine.

The Hub already includes a Process Analytics program that allows users to access real-time data from anywhere, build and export reports, view job audit reports, replay historical data and more. It also features Mold Transfer, which allows users to transfer molds by automatically generating machine-specific setup sheets, recommending compatible machines and providing a database to store and share documents across the organization.

RJG’s Hub now supports injection molding simulation programs.

Related Content

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

How To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.