Injection Molding: News in Sensors, Quality Monitoring, And Quick Mold Change

Priamus debuts simple on-machine quality monitor plus new styles of cavity sensors and a quick connect for cavity sensors in quick mold changes.

At the recent Fakuma show in Germany, Priamus System Technologies, LLC (U.S. office in Sterling, Va.) introduced several new products:

• The new Quality Monitor is an inexpensive alternative to the company’s FillControl process monitor. It’s based on the new BlueLine QDaq digital data-acquisition unit (below) mounted on the injection machine. This compact unit measures only 160 × 100 × 61 mm. It incorporates an OPC-UA interface, which is becoming the standard for Industry 4.0 connectivity or “the Internet of Things.” The device sends data from cavity pressure or temperature sensors and from the process to a server, the cloud, tablet, and/or smartphone. No special software is needed. A PC or tablet is connected to the QDaq only for setup, after which it operates as a stand-alone data collector and transmitter. Accessories for this system include a QScreen tablet for data display and color-coded LED lights to indicate process status relative to standards.

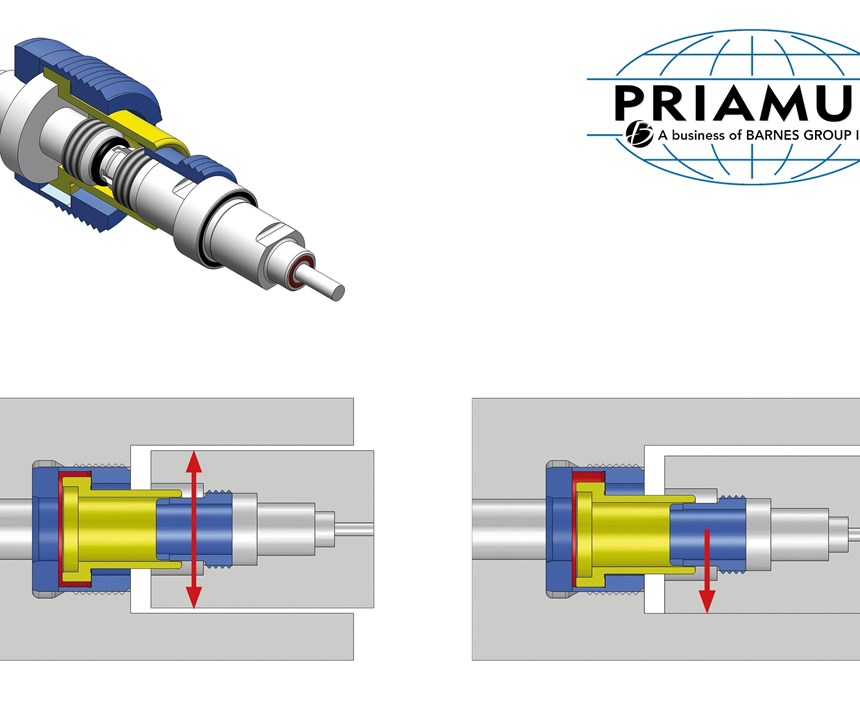

• Priamus also showed two new developments in sensors. One is cavity-pressure sensors with angled connectors. This minimizes the mounting space and height required by replacing the standard axial connection with a right-angled connection (see image). The side-outlet connecting cable is available for all standard sensors with automatic sensitivity detection and requires no modification of the sensors.

The second development is floating sensor disconnects for floating mold inserts. Priamus says floating mold inserts with generous tolerances are an increasingly popular option because they require less precise machining. The new disconnect system for cavity-pressure and temperature sensors automatically compensates for lateral displacement of the inserts.

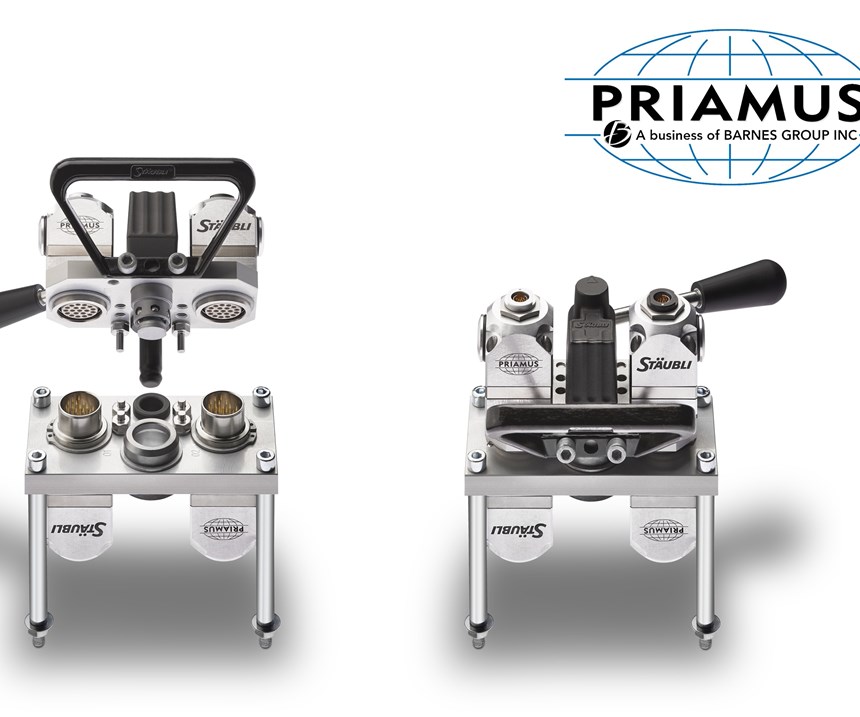

• For quick mold changes, Priamus’ new Mold Dock is the result of a collaboration with Staubli Corporation, which specializes in connectors for mold utilities in quick-mold-change (QMC) systems. Up to eight connector inserts for temperature or pressure signals are secured by a simple locking system and encoding pins. A manual dock is shown here; the inserts are also available separately for fully automated QMC systems.

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.