Injection Molding: Simple Robot Cell for Gate Cutting Needs No Programming

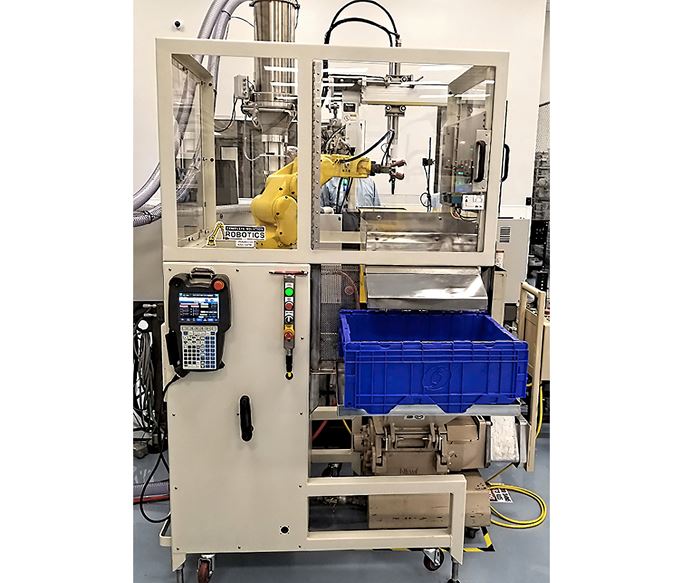

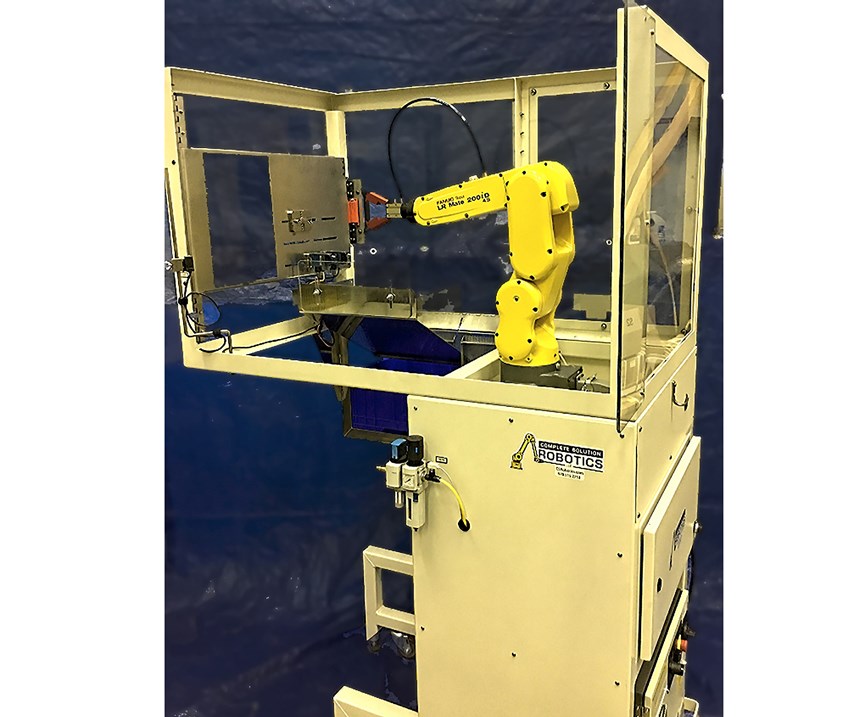

CS Robotics designed a small six-axis robot cell that can be rolled up to any machine and set up in minutes.

A custom robotics integrator has come up with a simple, low-cost solution to trimming parts from sprues that is flexible, mobile, and needs no programming knowledge. The O-Cut from Complete Solution Robotics in Loveland, Colo. (csrobotics.com), is a self-contained cell based on a small, six-axis Fanuc robot and a gate-cutting device (“nipper”). “The system can be rolled to any machine and set up in minutes,” says Michael Olson, the firm’s founder and owner.

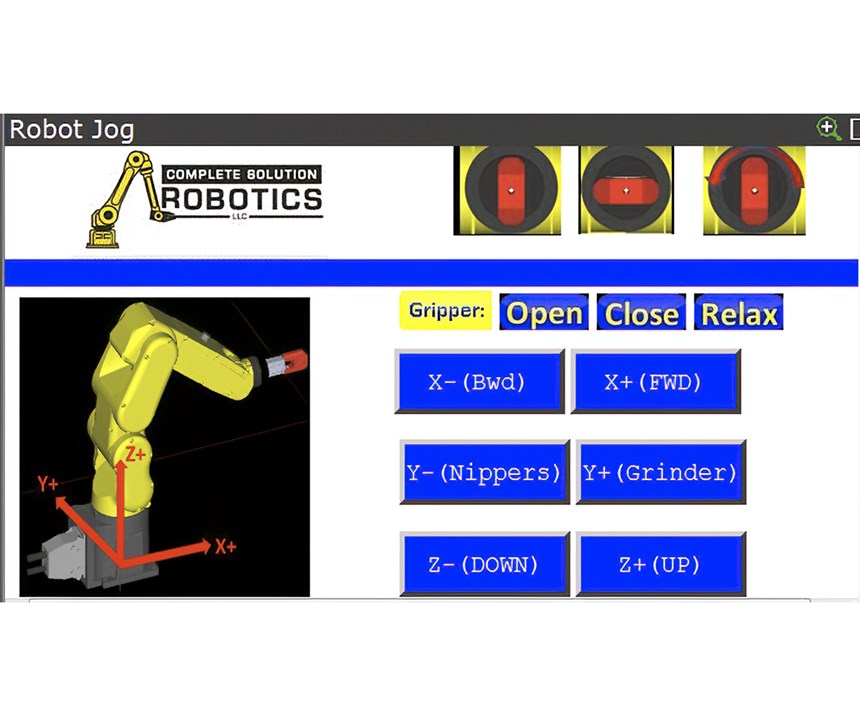

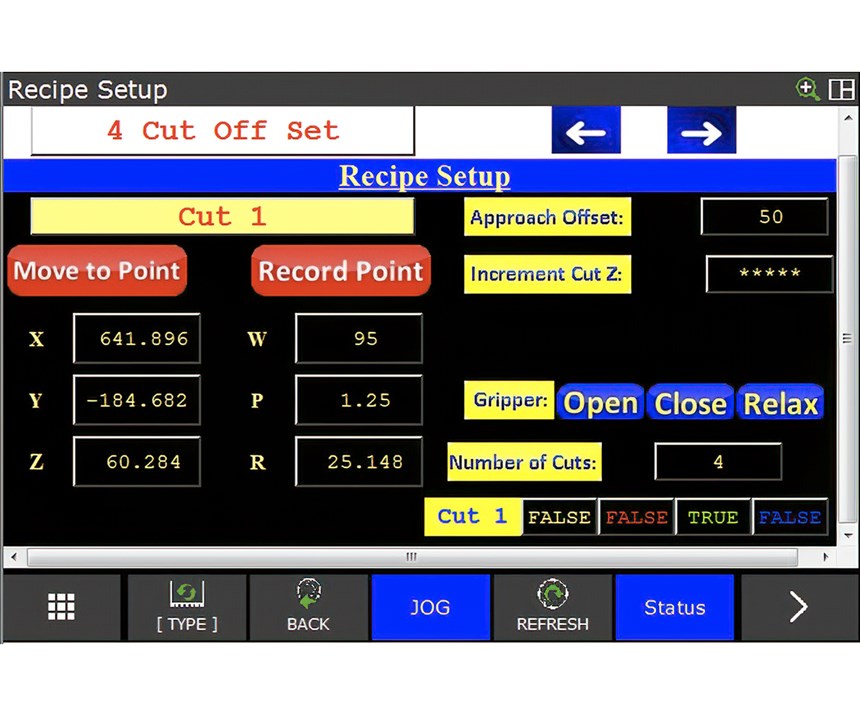

The robot grabs a sprue and attached part or parts from a sprue picker and then presents the parts to the nipper. The parts fall into a bin (or can be placed in a tray) and the sprue is dropped into a grinder. Setup involves a menu-driven recipe on the accompanying touchscreen. The robot is “taught” the operating positions using incremental “jog” commands for each axis, with fine adjustment by by direct entry of numbers. Points can be adjusted in 0.001-mm increments. Recipes can be stored for quick recall and can be shared between different O-Cut units. An operator can move the cell, fine-tune positions, and change cut sequences as needed. Multiple cuts are possible.

The robot has a 4-kg payload capacity and cut repeatability of ±0.02 mm. Hydraulic feet on the cell are adjusted via hand crank. In standard configuration, the sprue grinder, nippers and part bin are supplied by the customer, but options include the grinder and conveyor with indexing boxes or trays for cut parts. The unit sells for $50,000 without nippers or grinder.

Related Content

-

AI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

New Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.