Micro 3D Printer Creates Microscale Features

B9Creations’ Elite Micro 3D printer provides native pixel size of 20 µm with the ability to create wall thicknesses down to 30 µm and holes down to 100 µm.

B9Creations (Rapid City, S.D.) has launched the B9 Elite Micro 3D printer platform, delivering micro holes and thin walls that push feature size capabilities for an economical price. The company says the Elite Micro enables users to 3D print geometries that would be impossible to create any other way, with the ability to fabricate truly novel medical and industrial applications.

The company says the Elite Micro 3D printer’s feature size capabilities are at the scale and tolerances that nearly meet or exceed those of micro injection molded parts. Using digital light processing (DLP), the machine offers native pixel size of 20 µm with the ability to create wall thicknesses down to 30 µm and holes down to 100 µm.

B9 says the system is ready to print in just 15 minutes after opening thanks to factory startup assistance, and it never requires recalibration. Included software provides print preparation, management, and monitoring, as well as a streamlined workflow with automated cleaning and curing post-processing units.

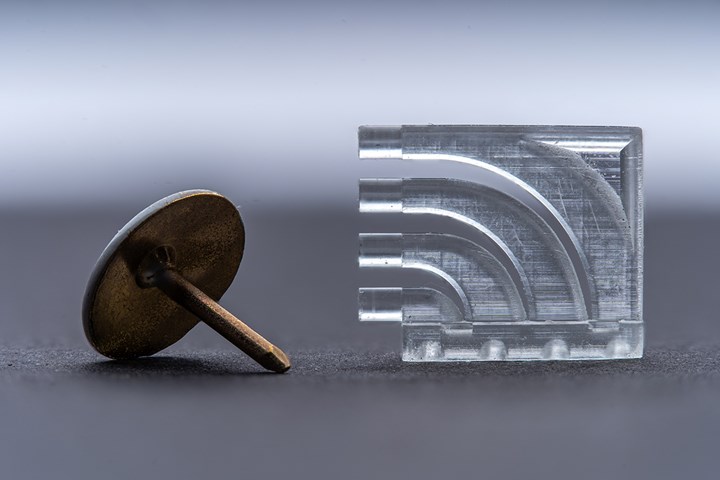

This part was printed on the B9 Elite Micro from the company’s HD Clear material, which allows for fully transparent parts with polishing or coating.

Photo Credit: B9

The printer can use B9Creations resins or third-party materials, or B9Creations can develop a custom resin. A company spokesperson told Plastics Technology that the machine uses liquid photopolymer resins that come in 1-kg bottles. The B9 Elite Micro can print from the company’s HD (high detail), HD Clear (“acrylic-like”), and Robust (PC/ABS-like) resins. The annual service package includes on-site training and installation, a dedicated customer success specialist, hot swap program, and more. The units are customizable by build volume, resolution and accuracy, materials, software, and more.

Regarding customization, the spokesperson said resolution and build volumes for tailored platforms range widely depending upon customer needs. Historically, the company has

customized machines from 127 mm all the way to 320 mm in z height, depending upon the application. It has also developed semi-custom platforms that enable high-resolution printing for elastomeric materials, and customized software for healthcare, aerospace, and jewelry customers to integrate into their workflows.

After parts are printed, they must be cleaned with isopropyl alcohol to get rid of any excess resin, and then cured in a UV post-curing unit. B9Creations offers automated post-processing accessories that include the B9Clean, an automated cleaning unit where parts can be transferred directly from the printer to the while still on the build platform or as loose models on the part tray, and the B9 Model Cure, a multi-wavelength UV post-curing solution for resin models.

This part was printed from B9’s HD Slate high-detail resin, designed for microscale components with zero “bleed” in the z axis.

Photo Credit: B9

Related Content

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.