Molds Promise Process Optimization for Smaller Carbon Footprints

Five Haidlmair tools running at K 2022 will showcase optimized cooling for faster cycles and the ability to run recyclate for more sustainable molding.

Coming off a record sales year and two years after it set out to make its own operations more sustainable, mold maker Haidlmair says its K 2022 focus will be on the sustainability of products its tools produce with five molds running at various partner companies.

The maker of tools for crates, logistics containers, pallets and more said it was able to achieve carbon neutrality in its operations in August 2021. With that milestone behind it, the company is hoping to lower the carbon footprint of the goods its molds produce by applying new technologies within those molds.

The first step in this process was the ability to determine the exact CO2 footprint of its molds, tracking everything from the production of the tool steel to its own machining to upstream and downstream transport. With that data in hand, Haidlmair says its focus is on compact mold designs and optimized cycle times to help reduce the energy requirement per part. It has also focused on tool designs that support the use of recyclates.

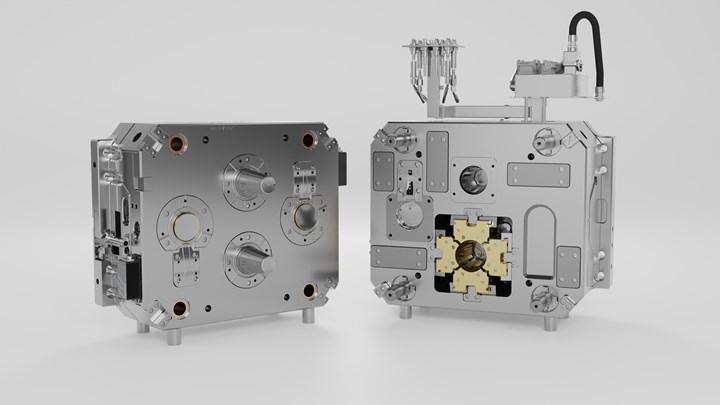

At Haidlmair’s booth, a mold for a six-drink crate will be running. The company says this mold demonstrates optimized design for running recycled material, as well as the use of it FDU (Flat Die Unit) hot runner technology from the Haidlmair subsidiary of the same name. In addition, the mold features real-time production monitoring and documentation via Digital Moulds Mould-Monitoring software. Cycle times were shortened by applying what the company called hybrid manufactured components made via conventional and additive manufacturing means.

An innovative “6-pack” design via a Haidlmair mold.

Photo Credit: Haidlmair

Two Haidlmair molds will be running at the booth of injection molding machine maker Engel. A mold for a dolly pallets made exclusively with recycled material is running in the Circular Economy Forum located in the outside area between Halls 11 and 16. The process runs polyolefin flakes processed directly without being pelletized. This mold also applies FDU and Mould Monitoring System technology.

A multiuse container mold will also be run by Engel, achieving a speedy 25-sec cycle time. That cycle time is possible thanks to communication between the mold and the Engel duo 8310/700 speed machine, with special care to avoid warpage which can result from such rapid temperature changes. To avoid part distortion, Haidlmair developed its own cooling station, on which the molded and still-warm parts are placed for additional cooling outside the mold until the potential for warpage is eliminated. The setup also features a thermal-imaging camera to track heat distribution across the molded part post molding.

This multiuse container mold will run in a 25-sec cycle time at Engel’s K 2022 booth.

Photo Credit: Haidlmair

At Wittmann Battenfeld’s booth, attendees can see a Haidlmair tool molding a reusable 3-component coffee-to-go cup. In addition to multi-material molding, Wittmann’s Cellmold foaming technology is also used to reduce the amount of material consumed. In the mold, hybrid elements designed to optimize cooling are built into the molding plate, applying conventional machining and 3D printing by using DMG Mori’s hybrid Lasertec technology.

At Wittmann Battenfeld’s booth, a Haidlmair coffee-to-go-cup mold will run applying Wittmann’s Cellmould foam technology and multimaterial molding.

Photo Credit: Haidlmair

Haidlmair’s fifth mold running at K will produce the Crinkle Box mini—a container mimicking a paper bag familiar to show goers. At K 2022, the mold will be exhibited at the booth of injection molding machine maker Milacron, utilizing the latest generation FDU SLS nozzle. Specifically the mold will run on Milacron’s new eQ model range, which will also utilize iMFLUX low-pressure molding.

Related Content

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreHow to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Haidlmair Spins Off New Hot-Runner Company to Sell Novel FDU Nozzle

Unique nozzle design for faster cycles at lower temperatures and pressures is now available to all moldmakers.

Read MoreHaidlmair Is Looking for a U.S. Moldmaking Location

Austrian mold builder wants to set up shop here.

Read MoreAnswering the Sustainability Challenge with Digitalization

Attendees in the molding halls of K can count on exhibits that address two main themes: digitalization and sustainability. Digitalization in the form of smarter pieces of equipment communicating with each other and with plant personnel; and sustainability in the form of greater energy efficiency and the ability to process recycled and renewable resins.

Read More