‘Next-Generation’ AI Defect Inspection Software

Mitutoyo’s new AI Inspect Software can be used with any vision inspection system.

A new AI inspect software from Mitutoyo America Corp., Aurora, Ill., that can be used with the company vision systems or any other vision inspection machine, has been designed to determine defects in multiple applications. Mitutoyo AI Inspect is a standalone software product designed to assist customers with next generation visual defect analysis and features multi-modular design: The software features two distinct modules--Training Module and Runtime Module.

Training Module: The main module of the software contains functionality to allow users to develop inspection routines for automated implementation of defect detection using image sets. Methodologies include:

▪ Project Management of Image Sets: Importation, organization, and storage of user defined inspection projects.

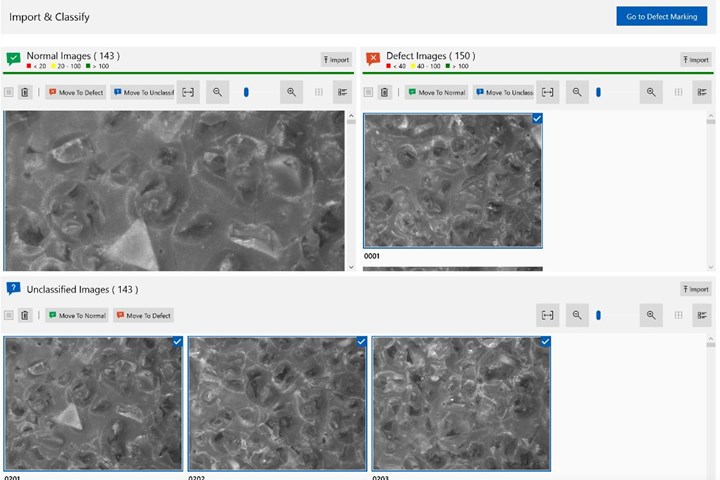

▪ Import and Classification: Integrated tool sets and techniques for loading and classifying both normal (good) and defect (bad) image sets.

▪ Defect Marking: A simplified user interface for the operator to mark-up/highlight defects on images.

▪ Training Setup: Allows the operator to perform a wide range of tasks, including training mode with Testing and Analyzation and Optimization of defect detection models. Additionally, the Image Augmentation section allows operators to apply advanced techniques to the inspection models such as Brightness, Noise and Focus to reduce the influence of typical image aberrational factors that may influence the accuracy of training model.

▪ Training: Provides status for the operator to visualize the progress and success of the training sequence.

▪ Results and Thresholds: A graphical GUI that allows the operator to review number of predictions related to the trained model. These include image classifications and predictions, pixel predictions and defect size thresholds, and the overall model prediction of normal, uncertain, defect and misclassified trained model components.

▪ Deploy: Publish the model for Inspection. Additionally, the ability to publish the model and provide a unique identifier completes the entire deployment process.

Runtime Module: The Runtime Module allows trained AI module to be incorporated into an inspection system. Included in the Runtime module model is the inference testing application that allows review of the AI model for sample testing on new images.

Related Content

-

How to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

-

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

-

Tracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.