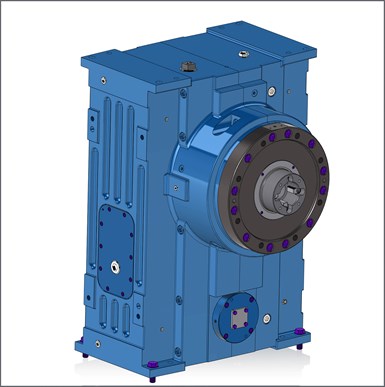

Next-Generation Gear Reducer is Sleek, Robust

Can accommodate a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures.

Davis-Standard’s next-generation gear reducer features a sleek new design and represents a commitment to customer feedback, field experience, and technical engineering while building upon the robust performance synonymous with Davis-Standard gear reducers. The new reducer fulfills a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures. It can also accommodate the DS Activ-Check system, Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts.

The new gear reducer is available in five different dimensions and capacities for extruders ranging from 2 in. (50 mm) to 6.5 in. (165mm). Reported advantages include:

Horizontal and vertical orientations : The horizontal orientation is said to be a good fit for belt-driven machines and/or low centerlines. This allows for a range of belt drives, versatile feedscrew timing, and adaptability to direct-coupled drives. The vertical housing arrangement is designed for direct-coupled and narrow footprint machines. It allows for tight positioning of extruders used in multilayer processes.

Image: Davis-Standard

Cooling and lubrication: There are two cooling and lubrication options based on housing style and customer requirements. These include oil bath lubrication and partial immersion/forced lubrication.

Gears and roller bearings: Case-hardened precision ground helical gearing is available in a wide range of gear reduction ratios to suit process requirements. New to this reducer series are spherical roller thrust bearings which absorb the axial process load and provide a self-centering, compact design with superior low-friction characteristics.

Radial shaft seals : All reducers are fitted with high-quality, spring-loaded radial shaft seals to contain lubrication oil and exclude contaminants.

Felt excluder: A felt ring excluder has been added to the front output shaft to protect the shaft and seal from abrasion and extend seal life.

Housing design: Durable cast iron construction provides quiet operation and minimal vibration. Large inspection ports simplify viewing of gear tooth condition, and a non-vented, bullet-type oil sight check eliminates the potential for leakage. Large oil fill ports allow for easier filling, while a low point drain port enables complete draining. A front thrust shaft cover completely encloses the reducer housing, allowing for more precision seal-to-shaft alignment.

Davis-Standard says the new gear case can be retrofit to older extruders in some cases.

Related Content

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

-

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.