Sepro Introduces Medical and Pharmaceutical Application Robot Line

Sepro Group says its MED Series of 3-, 5- and 6-axis robots is equipped with the features medical customers have been requesting for robots sold into ISO 7 and 8 clean room applications.

Sepro Group says its MED Series of 3-, 5- and 6-axis robots will meet growing demand for automation in clean rooms and other sensitive environments in medical and pharmaceutical molding plants.

In a release, Claude Bernard, product marketing director for Sepro, said the MED Series can be used across the entire production line in a clean room, from assembly to inspection, traceability and packaging. The Sepro MED robots include FDA-approved lubrication on all linear guiding surfaces and gearing. Cables can be protected in conduits and all robot surfaces are smooth and painted medical white with limited decoration so that dust does not accumulate, making cleaning easier.

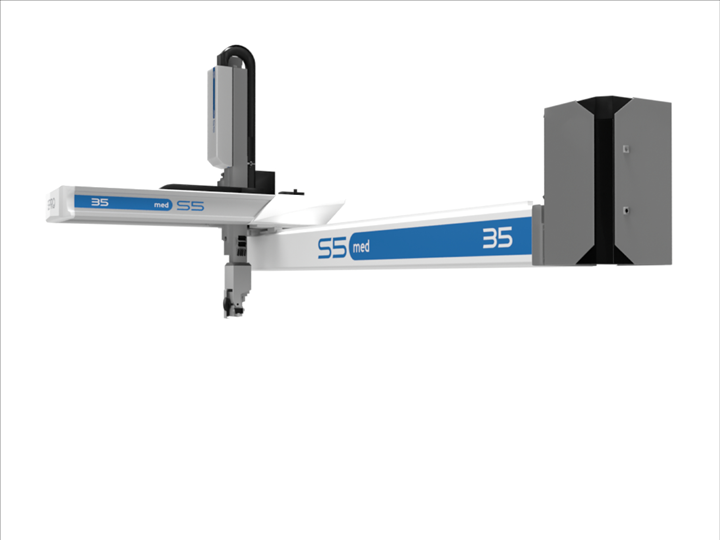

Only clean materials are used in many components—like end-of-arm tooling—that come into contact with molded parts. Places where grease or other lubrication is used are enclosed so that none can escape into the molding area. 5X MED robots include a two-axis servo wrist to provide a total of five numerically controlled axes of motion. S5 Line MED robots have three servo-driven axes and a pneumatic wrist. All robots can be optionally equipped with pneumatic filtration to 0.3 micron.

The 5X MED and S5 Line MED ranges include three different sizes of robots to serve molding machines with from 30 to 800 tons of clamping force. Nominal payload capacity (part plus end-of-arm tooling) ranges from 5 to 20 kg (11 to 44 lb). The robots can be installed in a conventional transverse or space-saving axial layout.

6-Axis Robots

Offered in collaboration with Stäubli Robotics, the Sepro 6X MED 6-axis-servo articulated-arm robots are described as “inherently clean.” The standard Staübli arms are certified for ISO 5 (Class 100) clean rooms without modification, but Sepro says the 6X MED robots can exceed the level of cleanliness possible with injection molding. Laminar air flow allows floor or ceiling mounted side-entry installations to meet the requirements of ISO 7 and 8. Four models are available to serve molding machines from 20 to 1300 tons.

Sepro Group’s MED Series targets medical and pharmaceutical applications with clean room ready functionality.

Related Content

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

DuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

-

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.