Single-Inlet Plenum Air Ring Improves Gauge Control

NPE2024: New design also eliminates multiple hoses to clean up production area.

Addex is debuting its first-ever blown film air ring with a single-inlet plenum design. While multi-inlet air rings have conventionally outperformed their single-inlet counterparts because they provide more uniform air distribution, Addex got input from film processors that running just one hose rather than the 4, 6, 8 or 10 that are typical of multiplenum designs would be beneficial. Having a single-inlet plenum eliminates the need to pull multiple hoses up and down every time the air-ring height is adjusted, Addex explains.

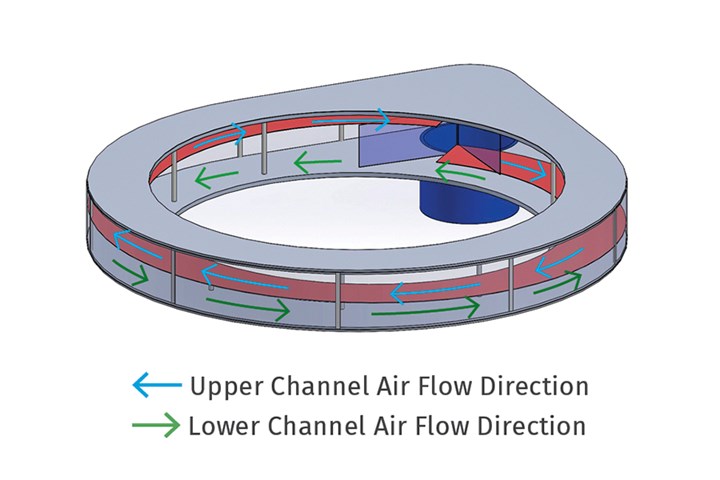

Addex set a goal to design a single-inlet plenum that performed equal to what it had achieved with its multi-inlet conventional plenum. Its solution was to apply a regular division design inspired by Dutch artist M.C. Escher, in which irregular shapes or combinations of shapes interlock completely to cover a surface or plane. Addex devised a patent-pending, dual-counterflow plenum design with one circular channel flowing clockwise all around, and a second going in the opposite direction all the way around. This creates the Escher “equal and opposite” effect, resulting in uniform combined air flowing through the air ring.

At its pilot line in Newark, N.Y., Addex switched between the new single-inlet design and the multi-inlet unit, both without auto-gauge control, and notes the single-inlet plenum provided better overall thickness profile with reduced variability.

Related Content

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

-

Why Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.