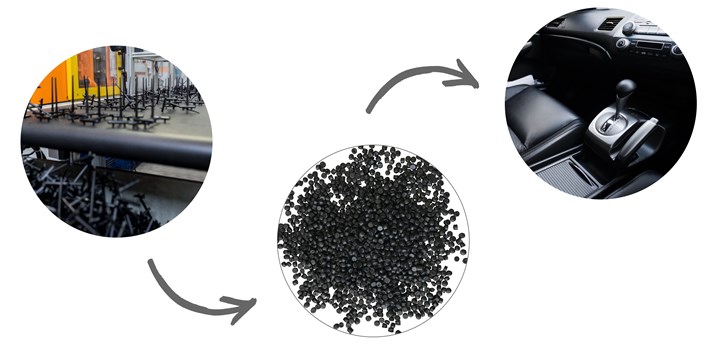

TPE with Recycled Content for Automotive Interiors

Hexpol TPE’s has expanded its portfolio of Dryflex Circular TPE grades with recycled content.

An expanded portfolio of TPEs with recycled content is now being offered by Hexpol TPE (U.S. office in Sandusky, Ohio). The new Dryflex Circular TPE grades have been tested for odor emissions performance in automotive interior applications such as inlay mats, cup holders, sealing lips and HVAC parts.

First launched in 2019, Dryflex Circular TPEs were developed to support the shift from finite fossil-based virgin materials. Recycled polymers from various sources, including PCR (post-consumer recyclate) and PIR (post-industrial recyclate), are incorporated into the Dryflex Circular TPEs. They can also be recycled in closed-loop systems at the end of life. An key aspect of automotive interior parts is their emission behaviour regarding odor and volatile substances. The exact specifications and requirements vary depending on application and OEM. But generally, the material odor must not be disturbing even at higher temperatures (e.g., 80 C/176 F).

A representative Dryflex Circular TPE grade, a 65 Shore A material for inlay mats with a recyclate content of 20%, showed a very low amount of VOC (60 μg/g) and FOG (594 μg/g). The TPE was tested at an external accredited laboratory and shown to have almost no odour (grade 2.0 according to VDA 270, B3). The mechanical properties fulfil automotive requirements, and colorability is possible. The material is currently being approved by a German car manufacturer.

The recyclate sources are diverted from waste streams during post-industrial manufacturing processes. They originate from injection molding sprues or edge trims in extrusions. The chosen recyclates were selected due to their high levels of consistency and purity. With consideration of transportation and energy impacts, the recyclates are sourced in Europe. Dryflex Circular TPEs are produced at Hexpol TPE's European sites, which use 100% renewable electricity.

Said group product manager Dr.-Ing. Thomas Köppl, "With the recent developments of Dryflex Circular TPE, it is now possible to realise high-performance interior applications. Together with our Circular TPE grades for exterior applications and our biobased TPEs, we are supporting automotive suppliers and OEMs to fulfil their targets to increase the use of recycled and renewable materials."

Related Content

-

Advanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

-

Prices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

-

Prices of All Five Commodity Plastics On the Way Up

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.