best practices

November’s Most-Viewed Stories

What did visitors to Plastics Technology read in November—the right injection machine for you; controlling and optimizing pack and hold times; resin pricing; polyolefins insights (compounding, density, strain rate); automating pipette production; improving mold cooling and more.

Read MoreMore Knowledge ... at a Mouse Click

Get to know the Knowledge Centers on Plastics Technology’s website.

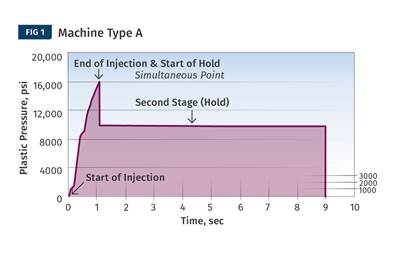

Read MoreHow Does Your Molding Machine Control Pack Pressure?

It seems some new machines have pack velocity issues, as machine builders are confusing processors with controllers that are more complicated than they need to be and less user-friendly.

Read MoreConsidering Scaling Up for More Output? Follow These Tips

Keep these calculations handy when you are trying to decide whether a bigger extruder will get you the output you need.

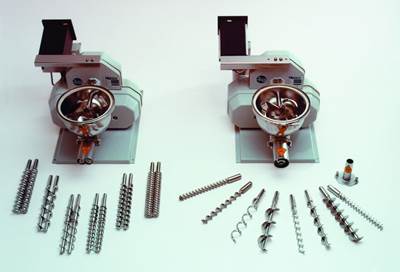

Read MoreUse These Twin-Screw ‘Tools’ to Improve Quality of Your Color Pigment Dispersions

A twin-screw compounding extruder is a single piece of equipment divided into distinct unit operations. Thinking of each unit operation as part of a toolbox can help determine what can be added or improved to process best-quality color masterbatches.

Read MoreScared Straight on Molding Simulation

Molding simulation is such a vital technology today that many molders couldn’t imagine life without it. But as a “consumer” of such a service, you have to know how to carefully critique the simulation results, which can hide a multitude of shortcuts and compromises that threaten their utility.

Read MoreFinding People Is One Thing – Keeping Them Is Another

Everyone bemoans the difficulty of finding workers. Are you doing enough to hold onto the ones you have?

Read MoreLooking to Handle More rPET? Don't Overlook Your Conveying System

There is a lot of important process equipment in PET recycling plants, and pneumatic and mechanical transfer systems connect them all. Downtime due to poor transfer system design, incorrectly applied components, or the lack of maintenance should not be a fact of life. Demand more.

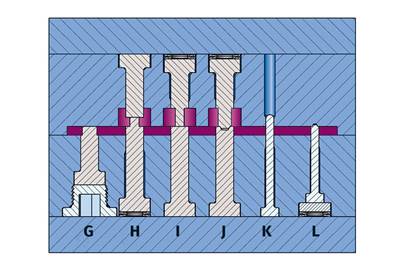

Read MoreHow to Form a Hole with a Core Pin: Part 2

Prevent wear, flash, and mold damage with these design methods.

Read MoreWhy Careful Hydraulic Oil Maintenance is Critical to Molding Machine Reliability

Here are the essentials on how to prevent one of the main threats to long-term reliability of your injection molding machines.

Read More