best practices

Residence Time and Residence-Time Distribution—Part 1 of 2

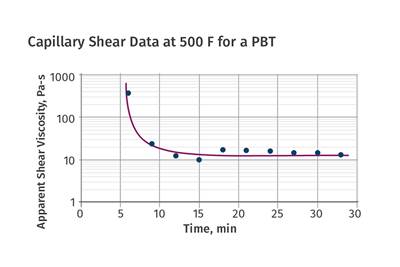

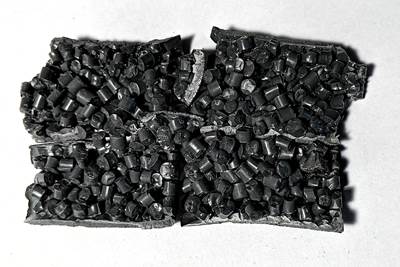

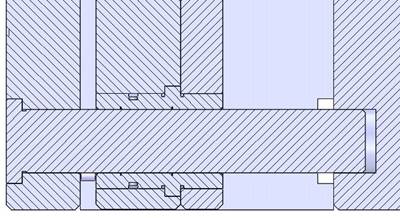

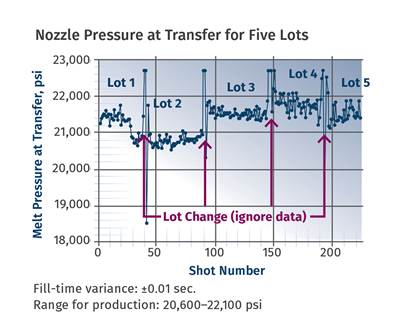

Failing to calculate and accurately account for residence time can compromise material integrity before it’s even injected.

Read MoreInjection Molding: Understand the Link Between Feed Throat Temperature & Bridging

Save time and money by properly controlling the feed-throat temperature. In some cases—but not all—it can help you solve a bridging problem.

Read MoreShopping for a Barrel? Consider the Full Cost of Ownership

Beyond just the “invoice price” of a barrel, processors should consider factors like the composition of the inlay, quality of the backing material, straightness, concentricity, machining imperfections and packaging/handling, to understand the true cost of owning a barrel.

Read More'10 Things We’re Seeing in Machine Shops Right Now'

Metalworking shops and plastics plants make for interesting comparisons of their responses to the COVID-19 challenge.

Read MoreHow to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

Read MoreFive Ways SPC Can Improve Performance

Statistical process control (SPC) can help plastics processors determine the factors responsible for product quality variation and provide a roadmap for improving the production process.

Read MoreUnderstanding the Effect of Polymer Viscosity on Melt Temperature

Every processor should get hold of the viscosity curves for the polymers they use or contemplate using in their operations, and learn how to read them.

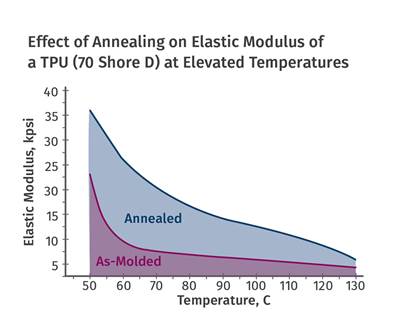

Read MoreMaterials Part 6 of 7: Annealing Tips for Thermoplastic Polyurethanes

TPUs form physical, rather than chemical, crosslinks that can be broken by reheating. Formation of these crosslinks can be sped up by annealing, which improves a variety of properties.

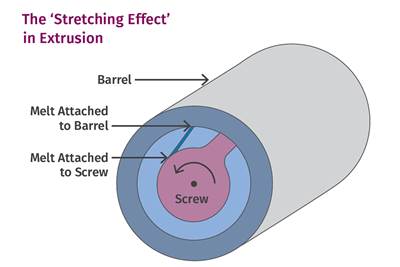

Read MoreFollow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

Read More