best practices

SPE Schedules First-Ever 'Virtual' ANTEC

Attendees can listen to keynotes and presentations live. Many presentations will also be recorded.

Read MoreHow to Optimize Usage of Recycled Material

Processors need to “engineer” feeding properties similar to virgin pellets into their regrind to efficiently and economically utilize more of their scrap.

Read MoreWhy—and How—You Should be Tracking Your Regrind

Ask yourself these questions to decide whether you need to implement a system to manage your scrap.

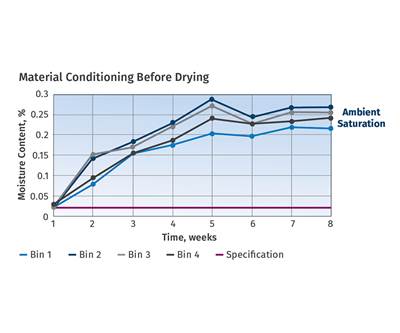

Read MoreUse a DOE to Improve Consistency of Your Resin-Drying Process

Conducting a drying design of experiments (DOE) will ensure your polymer is properly dried every time. Here’s how to do it.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

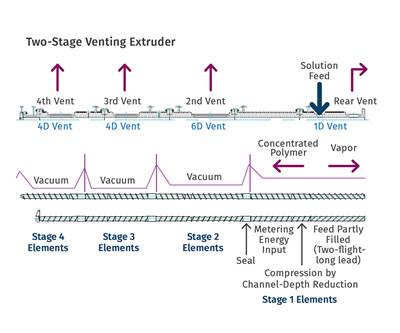

Read MoreCompounding: Part 1 of 2: Demystifying Devolatilization

Very little has been written about this critical topic, and most of what has been published is theoretical. Here’s some practical guidance to help you better understand the process and improve your operation.

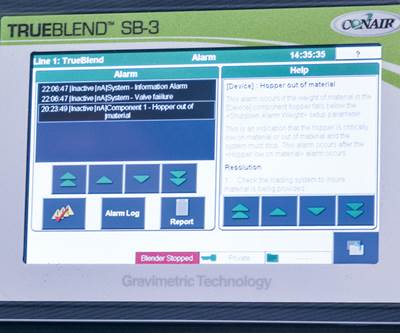

Read MoreAct Sooner, Not Later, on Auxiliary Equipment Alarms

There can be real financial, safety, and quality benefits for processors who train plant personnel to interpret and respond promptly to various alarms. Real-world examples offer proof.

Read MoreFinding the Right Melt Filtration System for Post-Consumer Recycling

To achieve high-quality pellets at the end of the recycling process, chose filtration technology based on both the input materials as well as the performance requirements of the finished material.

Read MoreInnovation, Customization & Sustainability: How Flex Films Focuses on U.S. Market

Global player in BOPET film has big plans for U.S. market with innovative products developed collaboratively with customers while paying heed to environmental concerns.

Read MoreCustom Molder’s Strategic Edge: Top-Class Metrology Services

Molding good parts is not enough. Better and faster metrology services for tool qualification and process validation make the difference for Octex Group.

Read More