best practices

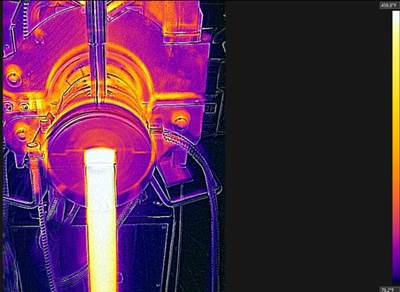

Five Factors to Consider When Molding PEEK

Are you a first-time molder of PEEK? Have you tried molding it and might be running into trouble? Take a look at five factors in the injection molding process that can help to avoid the need for troubleshooting when molding PEEK.

Read MoreExtruder Degassing: Is a Central System Right for You?

Centralization vacuum pumps have been used for many decades, most widely used in packaging. For extruder degassing the technology can be useful when several production lines are operated in parallel

Read MorePart Two: Determining Viscosity Data Using a Slit Die Viscometer

Using a slit-die viscometer connected to a lab extruder can generate accurate data on melt viscosity at various shear rates and different temperatures—a useful QC tool in processing.

Read MoreConveying Elbows Handle 40% Glass-Filled Nylon

Lighter and cheaper than cast alternatives, new stainless-steel conveying elbows utilize a plastics-specific geometry and proprietary internal coating to withstand filled materials.

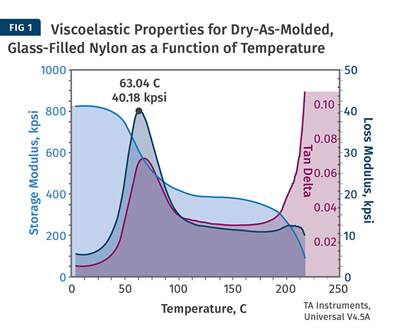

Read MorePart 5: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

In the final part of this five-installment series, we bring DMA to a practical level using the results for glass-filled nylon.

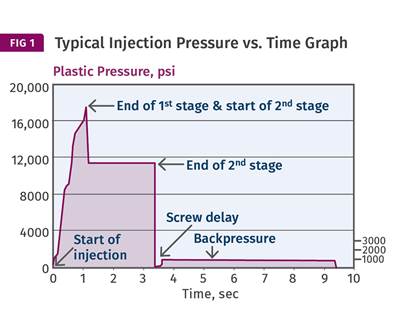

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

Read MoreImplementing Automation Systems: How to Do It Right

If you’re thinking of putting a complex automation system for high-volume consumables into your plant, consider these tips on making sure both you and your supplier are ready to give it the best chance of success.

Read MoreVIDEO: Injection Molding Experts Confront Industry’s Challenges

The technology divide in molding; worst practices; low pay and less training—a panel of injection experts tackled some of the tough issues facing processors today during a panel at Molding 2019.

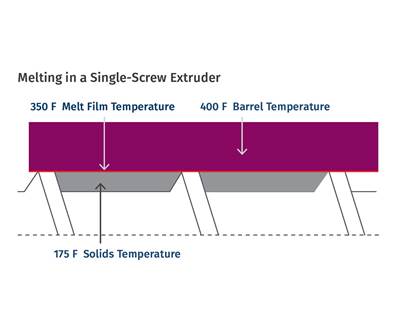

WatchWhy Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

Read MoreSolving the Bane of Stretch-Blow Molding: Off-Center Gates

There are many reasons why off-center gates happen, and processors should be aware of all of them to quickly find the ones causing the problem.

Read More