best practices

The 'Butterfly Effect' in Injection Molding—A Connected Process

In injection molding, a seemingly minor change in a setpoint can have a significant impact on part quality and process robustness and repeatability. That’s why Scientific Molding focuses on process outputs, not setpoints.

Read MoreThink Your Molding Operation Is Productive? Find Out How You Stack Up Against Others

Participate in Plastics Technology’s ”Top Shops” benchmarking survey and gain access to a free customized report measuring your key metrics against the cream of the crop.

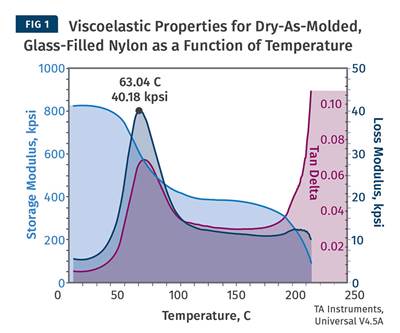

Read MorePart 4: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

The presentation of DMA data can sometimes frustrate users and discourage its adoption. Those unfamiliar with DMA should insist on receiving data relevant to the manner in which the part they are developing will be used.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProfile Processor Looks Beyond Windows and Doors

Intek Plastics intends to maintain a leadership position in its core fenestration business. At the same time, it’s on a mission to leverage its expertise in materials know-how, engineering, technology and customer collaboration to become a force in other profile extrusion markets as well.

Read MoreMold-Clamping Details for Profit

Taking time to sweat the details of clamping is not much fun, but they do make a difference in a company’s bottom line.

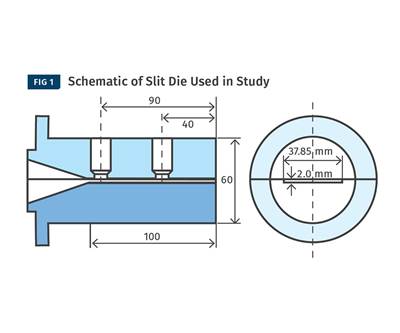

Read MorePART ONE How to Determine Viscosity Data Using a Slit-Die Viscometer

Using a slit-die viscometer connected to a lab extruder can generate accurate data on melt viscosity at various shear rates and temperatures, a useful QC tool in processing.

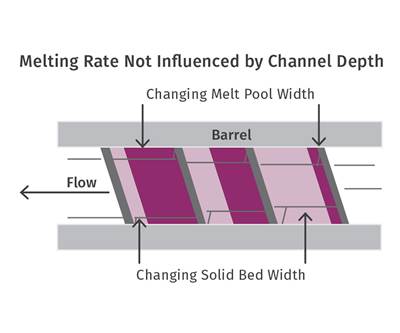

Read MoreSimple Scale-Up Calculations for Melting

You can avoid complicated melting equations when designing or evaluating a screw by using simpler methods that can save time and provide good results.

Read MoreHeat Deflection Temperature vs. Dynamic Mechanical Analysis (Part 3)

DMA provides a rich and detailed picture of polymer performance, and it can be challenging to understand all the things that we can and should know about our materials. But the fact that it may be hard does not mean that it should not be attempted.

Read MoreMolder Increases Capabilities—But Not Risk—With Flexible Two-Shot Technology

A customer request for multi-material molding presented a market opportunity and potential financial peril: How do you add two-shot without also overextending yourself from an investment perspective?

Read More