best practices

PART 2 OF 2: Tricks of the Trade on RTOs, RSOs

They have a lot more to offer molders than just shutting off a cavity. Let’s take a closer look.

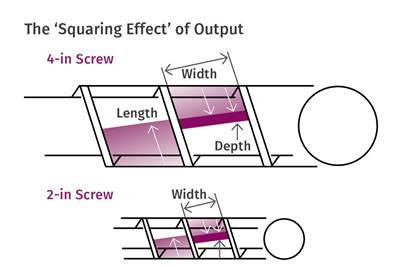

Read MoreUnraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

Read MorePART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MoreWorldwide Switch to New Gauging System Pays Off for Haartz

Leading supplier of sheet and roll stock for automotive applications reevaluated its thickness-measurement technology in 2012, and now has 15 scanners in place worldwide from one supplier.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

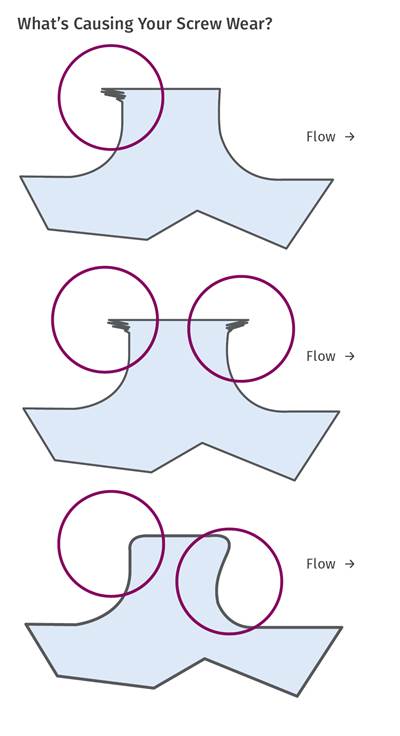

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

Read MoreTricks of the Trade on RTOs and RSOs

The more you know about these runner diverters and shutoffs, the more you’ll use them. Here’s how to put them to work in your mold..

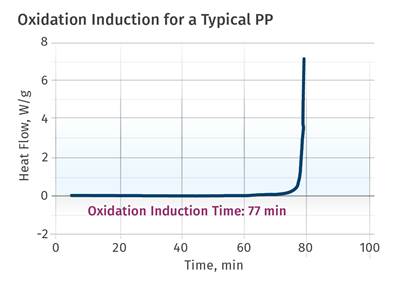

Read MorePart 11: A Processor's Most Important Job

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreA Gel By Any Other Name...

Gels…unmelt…contaminants…inclusions…whatever you call them, you want to avoid them. Proper maintenance and good housekeeping—lids on boxes, closed hopper doors, core-free reclaim systems—go a long way towards defect-free product.

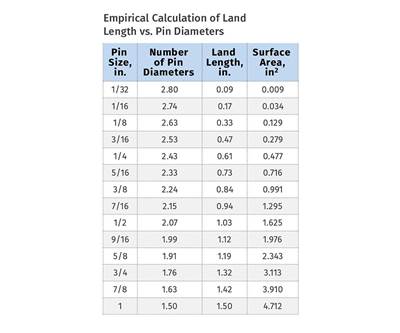

Read MoreWhy Ejector Pins Break and How to Prevent It: Part 4

In this installment the focus is on bearing length, clearances, keying, and machining.

Read More