best practices

Accredo’s Credo: Designed for Sustainability, Built for Success

In fewer than 10 years, Accredo Packaging has developed innovative packaging solutions—including the first-ever all-PE barrier standup pouch—while maintaining its commitment to being ‘green.’

Read MoreTooling: Why Ejector Pins Break And How to Prevent It, Part 2

Here’s the when and how to reduce the unsupported length of pins.

Read MoreInjection Molding: Is There a ‘Most-Important’ Process Parameter?

A case can be made for multiple variables—fill balance, fill time, injection pressure, cavity pressure—as most important. But there is something else altogether that is essential to successful injection molding.

Read MoreA Processor’s Most Important Job, Part 8: Molded-In Stress

How processing adjustments can control molded-in stress.

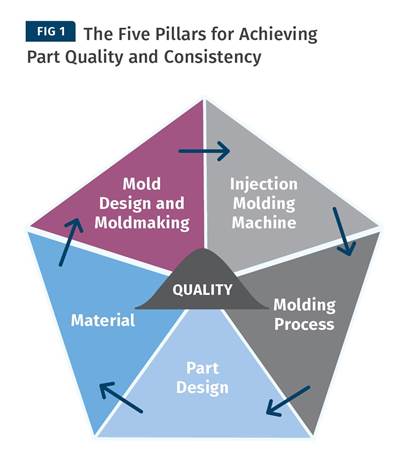

Read MoreImproving Molding Process Capability: The Role of the Five Essential Pillars, Part 2

Each contributes to molded-part quality, and each must be optimized before production begins.

Read MoreTooling: Why Ejector Pins Break...and How to Prevent It, Part 1

In part one of this four-part series, we focus on the molding machine and the ejection system as culprits.

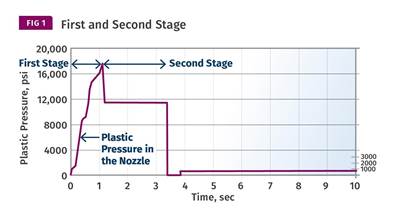

Read MoreInjection Molding: Fill Based on Volume, Not Weight

Most parts should be 90-99% full after first-stage—by volume not weight. Here’s why that’s important and how to make a first-stage-only part.

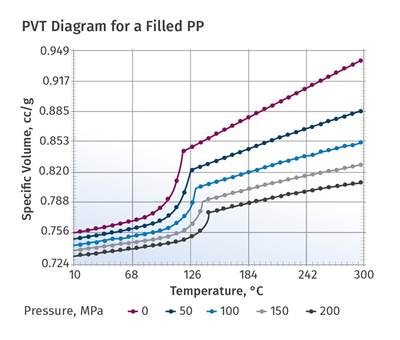

Read MoreA Processor's Most Important Job, Part 7: Reviewing Crystallinity

There are several process-related issues that influence crystallinity besides cooling rate. Let’s examine a few.

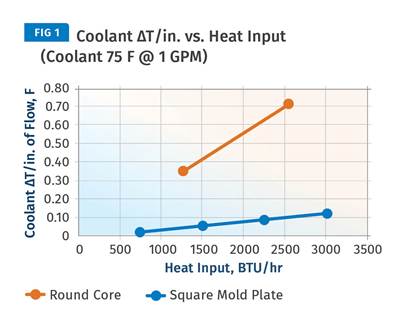

Read MoreAn Engineering Approach to Mold-Cooling Circuit Design

The Energy Density vs. ΔT/in. relationship is an important step forward in pursuit of a science-based approach to cooling-circuit design. Here’s why.

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read More