best practices

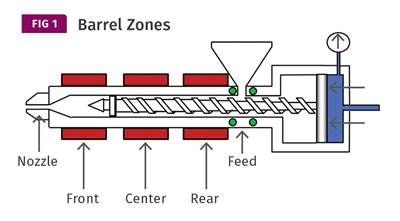

Injection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreA Processor’s Most Important Job, Part 3: Unintended Consequences

Processors are often expected to compensate for ill-advised decisions made earlier in the product-development process. In the case of shrinkage, one of the most common ‘fixes’ is to simply reduce the mold temperature.

Read MoreWhat is Your Extruder Trying to Tell You?

Being in tune with your film extrusion equipment will allow you to identify issues before they start impacting production.

Read MoreFollow These Tips to Power Up Your Purging Process

A properly executed purging process can save processors thousands a year in lost production while helping them increase output and avoid scrap. Here’s how to optimize your results.

Read MoreTooling: Tunnel Gates for Processors, Part 2

What you need to know to overcome problems out on the production floor.

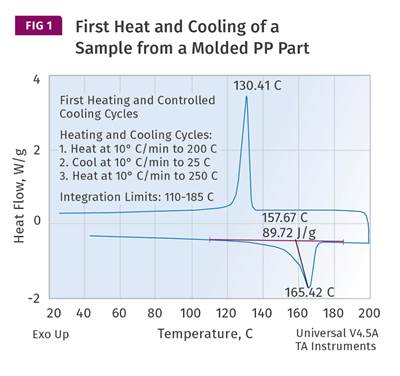

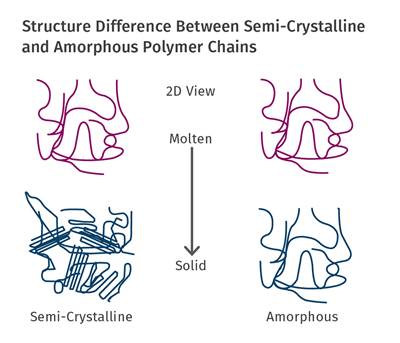

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

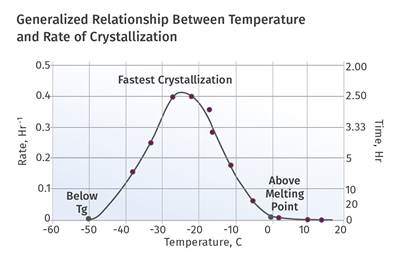

Read MoreA Processor’s Most Important Job, Part 2: Crystallinity

Process conditions help determine the difference between the maximum degree of crystallinity that can be achieved in a polymer and the degree that is present in a molded part.

Read More'Engage, Innovate, Evolve': Future-Oriented Culture at Octex Group

Using science, technology, and talent to give high-tech customers unprecedented speed to market.

Read MoreAir-Ring Upgrade Pumps Up the Output

Film processor Dallas Plastics boosts throughput by as much as 40% by retrofitting a new air ring—without the need for IBC.

Read MoreWhy Drying Polyolefins Might Be Right for Your Process

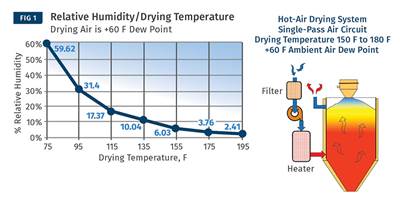

From a technical standpoint, drying non-hygroscopic materials such as polyethylene and polypropylene may not be necessary. However, doing so may be advantageous to your process. Here are details.

Read More