A Processor’s Most Important Job, Part 2: Crystallinity

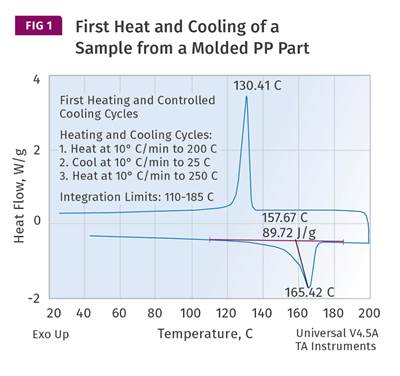

Process conditions help determine the difference between the maximum degree of crystallinity that can be achieved in a polymer and the degree that is present in a molded part.

This is part two of an eleven-part series focused on the most important job of a processor. To read the rest of this series, click these links:

part one, part three, part four, part five, part six, part seven, part eight, part nine, part ten, part eleven.

Thermoplastics are divided into two general classes: amorphous and semi-crystalline. The term semi-crystalline is used because in a commercial setting there is no such thing as a polymer that has achieved 100-percent crystallinity. That may occur in low-molecular-weight systems, but in polymers, the length of the chains and the myriad ways in which they can be arranged to prevent such a complete level of crystallization from occurring.

Of the commonly used commercial polymers, high-density polyethylene (HDPE) achieves the highest degree of crystallinity; and even in this instance, the level rarely exceeds 85 percent, even for the highest density grades. For many semi-crystalline polymers, the typical degree of crystallinity is less than 50 percent.

For all grades of materials capable of crystallizing, there is a maximum degree of crystallinity that can be attained. The shape and size of the crystals will depend upon several factors that are far beyond the scope of these articles, and a review of the scientific literature on the process of crystallization is very interesting but very complex. The focus of this discussion is the role that process conditions have on the difference between the maximum degree of crystallinity that can be achieved in a polymer and the degree that is present in a molded part. This difference plays a very important role in determining performance characteristics.

What is Crystallization?

Crystallization is a process that depends on time and temperature. While other factors come into play and will be discussed later, their effect on the final structure of the part is relatively small compared with the effects of time and temperature. For crystallization to occur, the temperature of the polymer must be below its melting point. The lower temperature reduces the mobility of the individual chains and allows the process of crystallization to begin. This process will continue until the temperature of the material drops below the glass-transition temperature (Tg). The Tg is the point at which the non-crystallized material, known as the amorphous glass, reaches a level of greatly reduced mobility. While the polymer is above its Tg, the mobility in the amorphous regions allows polymer chains to be added to the growing crystals. Therefore, the window of opportunity for forming crystals is below the melting point and above the Tg of the polymer.

Within that temperature region, the rate of crystal formation and crystal growth will vary. Often people will quote general rules of thumb, such as, “Crystals grow at their fastest rate halfway between the melting point and the glass transition temperature.”

If only it were that simple. But it is true that for every polymer there is a definable relationship between the temperature of the polymer and the rate at which crystals form. Generally, crystallization will occur at a relatively slow rate at temperatures just below the melting point. The rate will accelerate as the temperature declines, reaching a maximum crystal growth rate at some point. Beyond this point the rate of crystallization will slow, and once the temperature declines below the Tg the process will stop altogether. A generalized pattern for this behavior is shown in the accompanying graph. This graph applies to natural rubber and is therefore not that useful for plastic injection molding. But the overall pattern that it displays is common to all polymers.

There are a couple of very important points contained within this graph. First, in a semi-crystalline polymer, the cycle time is governed to a significant extent by the rate at which the material achieves a certain modulus. This modulus, in turn, is related to the number and size of the crystals that form. The faster the crystals form, the faster the part can be demolded. The graph shows that at some point, reducing the temperature of the mold, probably the most common tactic that processors use to reduce cycle time, can be counterproductive. Even more important, reducing the mold temperature will reduce the degree of crystallinity that is achieved within the molded part. This is where the performance element of the discussion comes in.

We choose semi-crystalline polymers over amorphous polymers for a variety of reasons. Among these are improved chemical resistance, environmental stress crack resistance and fatigue resistance. In addition, a higher degree of crystallinity is associated with higher strength and stiffness.

If the polymer is not given the opportunity to crystallize, these properties will be compromised. There are other benefits of increased crystallinity. One of these is the degree of modulus retention above the glass transition. One of the key benefits of semi-crystalline polymers is that they possess useful solid-state properties above their Tg. While amorphous polymers essentially soften and become useless as load-bearing materials above their Tg, semi-crystalline materials, even when unfilled, will retain 10-30 percent of their modulus. For example, an unfilled PBT polyester, with a room-temperature modulus of 340,000 psi (2340 MPa), will still have a modulus of 48,000 psi (330 MPa) at 212°F (100°C).

Have questions about materials? Learn more here.

This retention can be improved by incorporating fillers such as glass fibers into the material. But if the material fails to achieve its intended degree of crystallinity, the expected modulus retention at elevated temperatures will be reduced. This can have implications for creep resistance, as we will show in a later article.

Another benefit of higher crystallinity that is often overlooked pertains to the way that nylons interact with moisture. As nylon parts absorb moisture they lose strength and modulus. They also exhibit changes in dimensions. As nylon parts take up moisture they swell. But the moisture is only absorbed by the amorphous regions of the part. Therefore, the more crystalline the material in the part, the smaller the effect of the absorbed moisture will be on critical dimensions.

Since the cooling rate is a critical factor in determining the degree of crystallinity in a semi-crystalline polymer, the mold temperature selected by the processor will be important to part performance.

Part geometry will, of course, be an important aspect of this picture. The wall thickness of the part is a significant element in determining a cooling time, and it will always be the case that material that is in direct contact with the mold wall will cool more rapidly than material in the center of the wall. This means that the degree of crystallinity in any molded part will vary with location. But part geometry is a constant. Mold temperature is a variable that is set at the discretion of the processor. Often, the selection of a mold temperature is made without any awareness of its importance to the performance of the part.

Higher mold temperatures will typically promote a higher degree of crystallinity if the mold temperature is somewhere on the left side of the curve in the graph. But raising the mold temperature is usually considered to bring with it an automatic penalty in cycle time. For some materials this may be true. Polyethylene has a Tg well below room temperature.

Studies show that the peak crystallization rate for polyethylene is also below room temperature. For materials like this, colder is better and there is likely no downside to part performance. But with higher performance engineering polymers, where the Tg is well above room temperature, lower mold temperatures can introduce a wide range of problems that may not be apparent until the part is in use.

In our next article, we will look at some examples of the unintended consequences of attempting to improve productivity by reducing mold temperature.

About the Author

Michael Sepe

Michael Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe LLC, is based in Sedona, Arizona. He has more than 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting and failure analysis. Contact: 928-203-0408 • mike@thematerialanalyst.com.

Related Content

Fundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MoreThe Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MorePolymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

Read MoreRead Next

A Processor’s Most Important Job, Part 3: Unintended Consequences

Processors are often expected to compensate for ill-advised decisions made earlier in the product-development process. In the case of shrinkage, one of the most common ‘fixes’ is to simply reduce the mold temperature.

Read MoreA Processor’s Most Important Job, Part 1: Molecular Weight

Many processors don’t realize that preserving material characteristics is crucial to product success and failure. The focus here is on molecular weight.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

.jpg;width=70;height=70;mode=crop)