best practices

Molder Gets Hermetic Seal, High Yield with Servo Welder

Supplier of power protection systems avoids redesign of molds by replacing pneumatic ultrasonic welder.

Read MoreMold Performance: Tap Into the Power of Data Collection

Collecting core data in a transparent way allows molders to drill into the true cost of tooling issues and develop real goals to keep production flowing.

Read MorePolymer Resources: Compounding's 'Small Big Guy'

This compounder combines a service-first, small-company mindset with the technical might of larger companies to carve a niche in engineering plastics.

Read MorePolyolefin Discoloration: New Additive Solutions Solve Common Problems

There’s a growing demand for PE films with lower initial color and improved color stability, as well as better retention of physical properties. New stabilizer systems address these and similar concerns for molded PE and PP parts.

Read MoreTooling: Critical Design Considerations for Sprue Bushings

Among them are good cooling, proper orientation, solid retention, structural integrity, generous radii, and an appropriately polished bore.

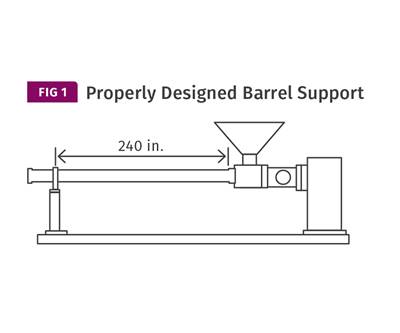

Read MoreExtrusion: The Importance of Proper Barrel Supports

Supports that allow the barrel to expand and contract easily will prevent alignment issues. Examine them periodically for proper operation, particularly if you’re experiencing excessive wear.

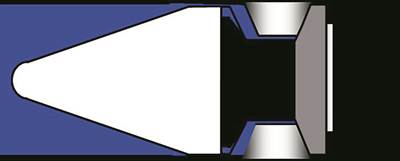

Read MoreInjection Molding: Time for Another Look at Non-Return Valves

First and foremost, they must seal properly, and check valves with stepped angles or radiused seats perform the best.

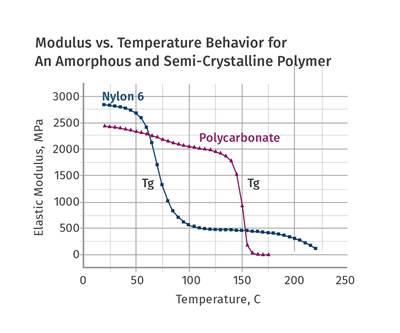

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 2

Understanding cooling—how a given material develops modulus as it solidifies—requires access to data that provides some insight into the relationship between modulus and temperature. Dynamic mechanical analysis is a helpful tool.

Read MoreUnderstanding Low-Rate Feeding for Continuous and Batch Processes

Molders and extruders that need to feed tiny amounts of material to their process require precision in both the material being fed and the equipment doing the dosing. When a shot size consists of three pellets, there is no margin for error.

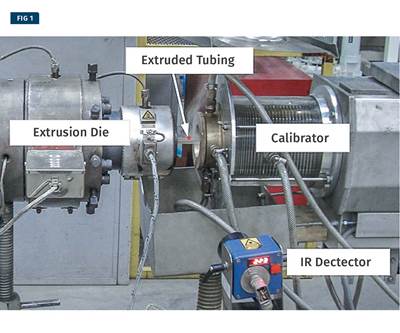

Read MoreHow to Collect and Interpret Extrusion Process Data; Part 3

In this final installment, learn how process data can be used to identify and fix extrusion issues.

Read More