best practices

Improving Molding Process Capability: Understanding the PVT Graph, Part 1

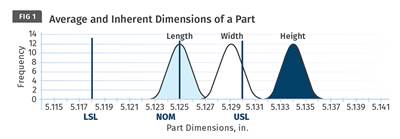

Process capability is related to the variation in part dimensions from shot to shot. High values of process capability require the shrinkage of the material to be identical on each shot, which can be confirmed from the pressure-volume-temperature (PVT) graph.

Read More‘Follow the Plan’ When Installing and Commissioning Compounding Lines

A fully operational and documented system doesn’t happen by chance. An efficient, well-designed installation plan, prepared well in advance, will put you on the path to maintaining a timeline and budget.

Read MoreGetting Started with Medical Molding: First Consider the ‘Four E’s’

Global medical molder Nypro provides first-hand guidance on what you need to get into the medical molding business.

Read MorePlastics-to-Oil Recycler Finds New Niche in Polystyrene

Agilyx is in an innovative area of recycling: extracting value from waste plastic streams. The company has expanded to develop the first full-circle chemical recycling of PS.

Read MoreTooling: Clamp Pressure and Cavity Land Area

What you need to know to prevent flashing and mold damage.

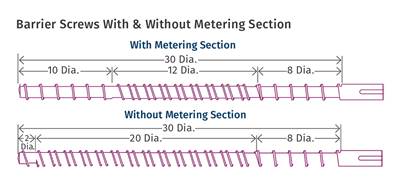

Read MoreExtrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

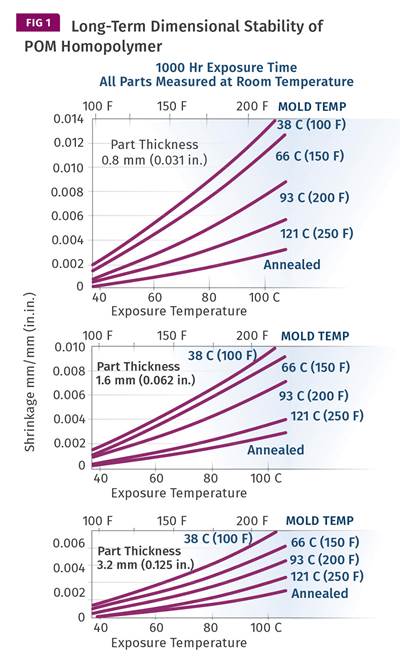

Read MoreA Processor's Most Important Job, Part 5: POM Polymers

Using a mold temperature above a polymer’s Tg ensures a degree of crystallinity high enough to provide for dimensional stability, even if the part must be used at elevated temperatures. But POM is an exception. Why?

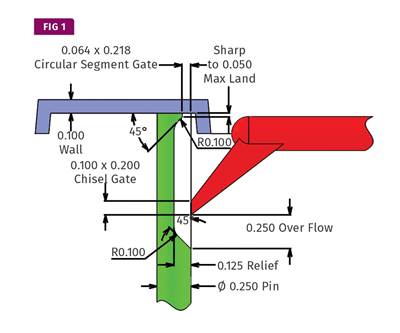

Read MoreTooling: What You Need to Know About Jump Gates

Many molders don’t care for jump gates because they have to process around them. But here are some tricks of the trade.

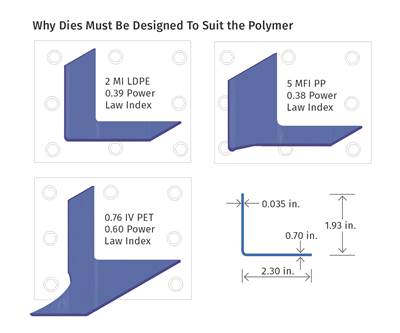

Read MoreExtrusion: Why There Are No Truly Universal Dies

Flow characteristics of different polymers vary considerably. So while adjustment features are available, for the most part dies must be designed for an individual polymer.

Read More