best practices

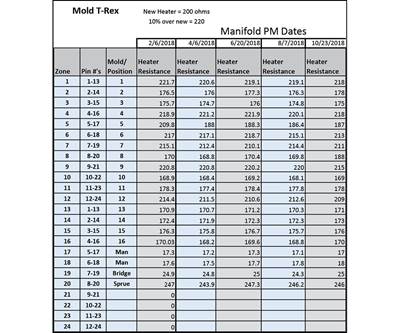

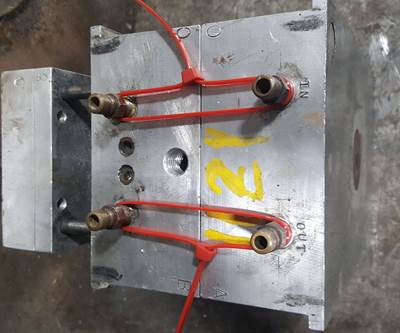

Time to Turn Up the Heat on Your Hot-Runner Maintenance Program

Molders are running more hot-runner manifolds than ever, a trend that’s expected to continue. But once you have them, you need to keep them in shape. Follow these tips to get going.

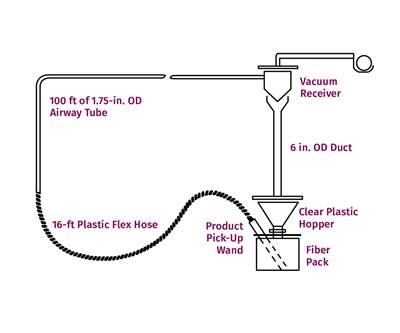

Read MoreWhat’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

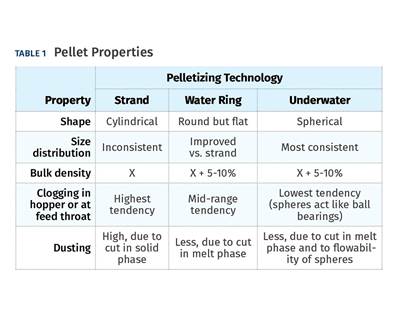

Read MoreFollow These Guidelines to Select the Right Pelletizing System

Which pelletizing system is right for your application? Is the one you’re using today necessarily the right choice for tomorrow? Here’s is an analysis that can help you decide among the three major options.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

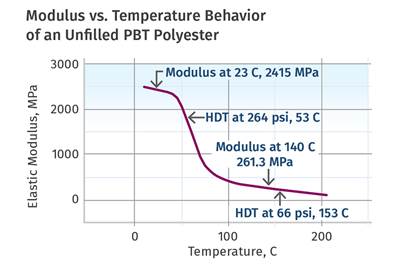

Read MorePART 2 Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Here’s a real-world example of a part failure demonstrating why DMA curves have more value than single-point data generated by HDT.

Read MoreCreating Tomorrow’s Workers Today

Plastics processors are increasingly taking matters into their own hands when it comes to bridging the yawning skills gap, drawing a sharpened focus on high schoolers. Could Switzerland’s apprentice system provide a model?

Read MoreThe Top 10 Most-Viewed Plastics Technology Articles of 2018

Sinks, flash, gels, weld lines—many of the most-viewed articles at PTOnline.com in 2018 offered processors advice on how to deal with some of plastics most nettlesome problems.

Read MorePlastics Technology’s Most-Viewed Columns of 2018

Here are the expert columns that visitors to PT’s site viewed the most in 2018, covering mold and melt temperatures; shot sizes; barrel capacity; material properties and more.

Read MoreProcess Capability and the ‘Hesitation Effect’

Understanding the concepts of pack and hold and applying them during process development is critical for molders to achieve consistent part quality.

Read MorePart 1: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Does the industry need a better way of reporting the temperature-dependent behavior of plastics? With DMA, it already has one. But it’s been glacially slow to catch on.

Read More