best practices

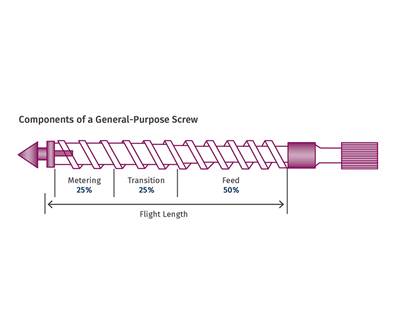

Revisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

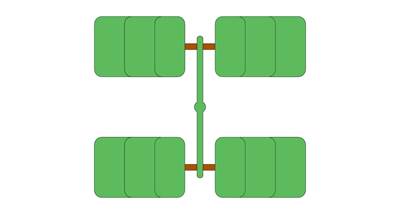

Read MoreSave Time, Money: Use a Mold-Design Checklist

Here are 15 examples of common molding issues that occur during an initial mold trial. Many of them could be avoided or corrected with a proactive checklist.

Read MoreStrand Pelletizing: Follow These Steps to Determine Your Water Bath Length

Use heat-transfer equations as a shortcut to get you in the ballpark of how long your pelletizing water bath should be.

Read MoreWhat You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

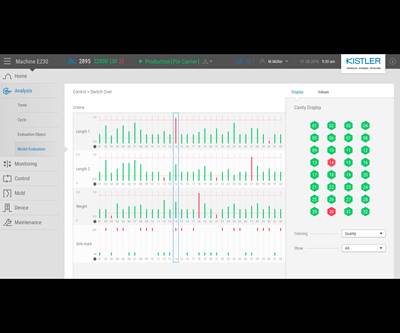

Read MoreHow Can Molders Achieve Effective Process Monitoring?

You have developed a proper process; now you need to monitor that process to ensure its stability through a run.

Read MoreMaterials Knowledge Pays Off at Teel Plastics

Well-equipped and well-staffed testing lab elevates competence of custom processor.

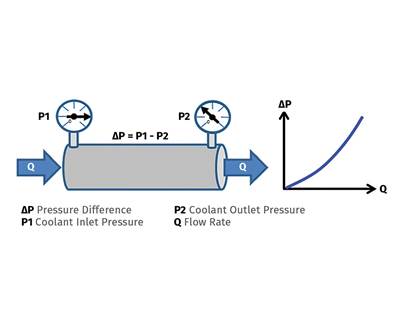

Read MoreIs Your TCU Up to the Job? Mold Simulation Can Give the Answer

For realistic results, molding and cooling simulation must reflect the capabilities of the actual TCU to be used. Here’s how simulation can help determine whether your TCU is up to the job.

Read MoreFollow These Steps to Purge Accumulator-Head Blow Molders

Preventive purging with a commercial product between resins or colors and during normal shutdown and startup cycles can prevent excessive loss of resin and production time.

Read MoreHow to Prevent Nozzle Tip Leaks, Part 2

Your very costly mold in that very expensive press is relying on the performance of a $20 nozzle tip that no one ever checks, and has a high probability of not doing its job. Stop learning from your mistakes and start learning how not to make them.

Read More