best practices

Achieving Continuous Improvement Using SMED Programs

A good SMED quick changeover program can help optimize financial performance by converting non-value-add time into value-add time.

Read MoreExtrusion: The Importance of Zone 1 Barrel Temperature

Tweaking the temperature settings of the first barrel zones may not yield the desired result. In fact, they may yield the opposite. Here’s why.

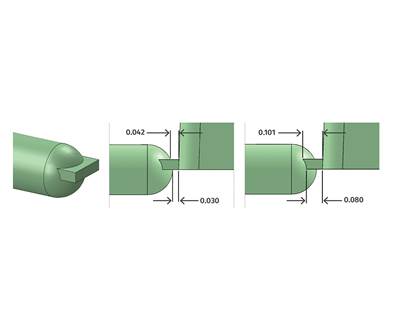

Read MoreTooling: How to Properly Size Gates, Runners and Sprues, Part 4

How to get the sprue, runner and gate sizes close to ideal the first time around.

Read MorePart 3 Materials: Annealing Tips for Semicrystalline Polymers

For these polymers, annealing is done to establish a level of crystallinity that cannot be practically obtained within the parameters of a normal molding cycle. Here’s some guidance on setting annealing time and temperature.

Read MoreFundamentals of Proper Press Shutdown

Press shutdown procedures have a significant impact on achieving smooth machine startups and restarts to improve uptime. Here’s a procedure you might want to deploy in your molding operation.

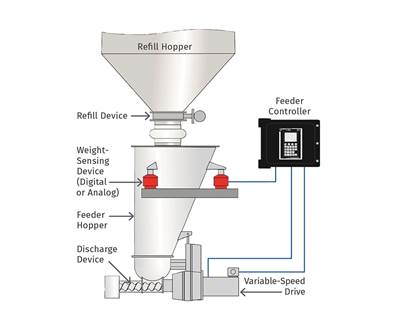

Read MoreIs Your Feeding Technology Robust Enough?

Maybe not. But consider these factors to beef up your system to ensure reliable and even smarter performance.

Read MoreBest Practices in Processing with Recycled Material

Inside: What brand owners are planning, and how processors ahead of the curve have already responded.

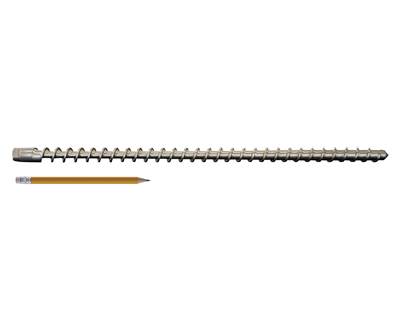

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

Read MoreTooling: How to Properly Size, Gates, Runners and Sprues, Part 3

Get the sprue, runner and gate sizes close to ideal the first time around.

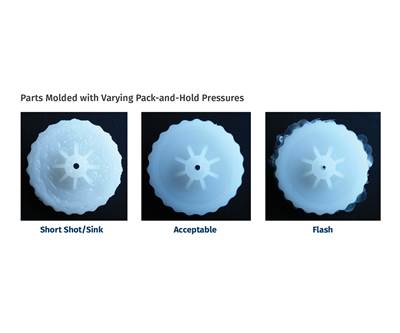

Read MoreThe Cosmetic Process Window: Key to a No-Tweak, Robust Process

Establishing a process with the widest possible cosmetic window can help put your injection molding on cruise control.

Read More