best practices

Workforce Instability and How to Avoid It

How employers can support employees who live in economic instability.

Read MoreSecrets of Quick Part-to-Part Changeovers

Part-to-part changeovers can be fast only with proper advance planning. Here’s what you need to know to convert from sluggish to swift in job changes.

Read MoreWhat You Need to Know About Blade Ejectors: Part 3

Follow these guidelines to prevent premature wear, flash and galling. The focus here is on corner radii.

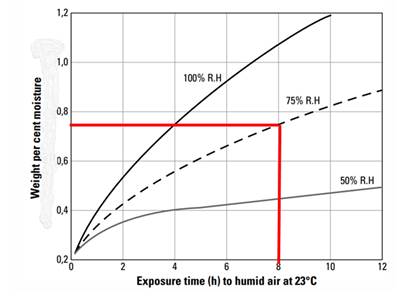

Read MoreFollow These Seven Management Tips for More Consistent Resin Drying

Equipment and advice sure help, but ultimately, good management makes the difference.

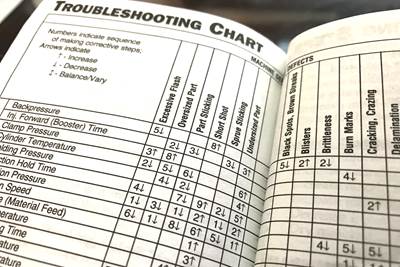

Read MoreApply the Power of a Troubleshooting Checklist to Your Process

Pocket guides provide processors an injection molding “crib sheet,” but in a process with thousands of interactions, applying if-this/then-that logic can’t always get you to a problem’s root cause.

Read MoreHeard of Design for Manufacture…How About Design for Maintenance?

Contract manufacturer Canon Virginia (yes, that Canon) used a webinar to introduce what it calls DFM2— Design for Manufacture and Design for Maintenance.

Read MoreWhen It Comes to Maintenance Trust Your Nose (and Ears and Eyes)

An ever-growing number of sensors on injection molding machines provide real-time transparency into a press’s inner workings, but the low-tech sensors humans come with are still vital to keeping a plant running.

Read MoreSolve Five Common Problems in Blown Film Coextrusion

The blown film industry has evolved from monolayer film structures to multilayer ones for a variety of food and non-food packaging applications. Here are typical problems with these structures and tips on how to solve them.

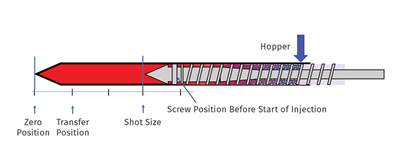

Read MoreConsider the Cushion When Seeking Shot-to-Shot Consistency

Creating and maintaining a consistent cushion is a key step in achieving shot-to-shot consistency. Learn what cushion is and how it affects part quality.

Read MoreNew Technology Adoption as a Business Strategy

As a company, is your adoption of new technology passive and by accident or strategic and planned?

Read More