Heard of Design for Manufacture…How About Design for Maintenance?

Contract manufacturer Canon Virginia (yes, that Canon) used a webinar to introduce what it calls DFM2— Design for Manufacture and Design for Maintenance.

Drawing from his decades of experience in molding and mold making, Wayne Daniel, director of business development, Canon Virginia, shared in a webinar with Plastics Technology, what his company calls DFM2— Design for Manufacture and Design for Maintenance.

Traditional DFM looks at a finished product or component through the lens of the process that will be used to fabricate it, and, working backward from that, creates a design that can repeatably and reliably be generated. Advances in simulation have furthered DFM to include the ability to predict the robustness of the manufacturing process itself in the case of injection molding.

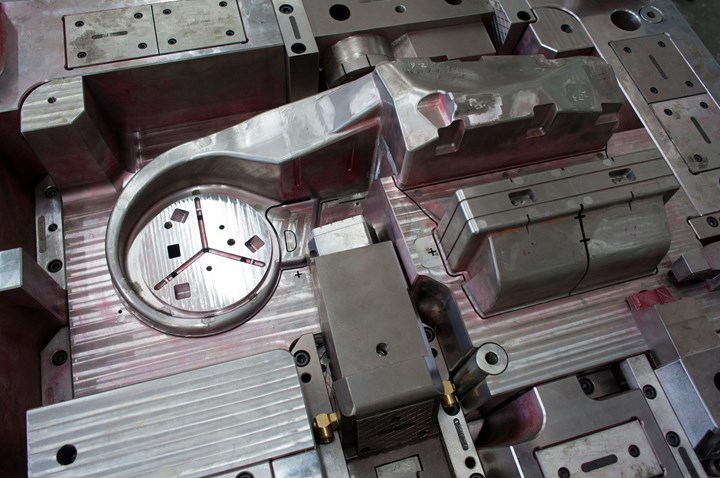

So what is Design for Maintenance? Basically looking at a tool design through the prism of what its maintenance will look like on the bench or, better yet, in the press.

In the webinar, Daniel noted that from his time running a shop with 100 active molds, he became very familiar with the aspects of a tool’s design that made them easier to maintain vs. those that did not. Done right, this DFM can not only boost a shop’s productivity, by reducing or eliminating downtime, but it can extend a mold’s life by some pretty stunning margins.

According to Daniel, Canon was able to able to gradually eliminate the need to replace its internal tools. At one time, the company counted on having to replace a mold after one million shots. This was extended to two million and then three million before the shot count was extended indefinitely. “We have completely eliminated tool replacement,” Daniel said. “I haven’t budgeted for replacement tooling in several years now.”

Through things like component standardization and implementing design advances in each new generation of tooling, Daniel said Canon was able to not only reduce the time needed for preventive maintenance and also cut down or eliminate human errors in mold reassembly. This also benefited inventory management by reducing the amount of buffer inventory the company had to keep on hand in anticipation of mold’s being out of action during maintenance.

Check out a recording of the webinar to learn more and get your shop closer to eliminating tool replacement from your plant’s vocabulary.

Let a tool’s maintenance regimen guide its design.

Related Content

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

-

The Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.