Materials Part 6 of 7: Annealing Tips for Thermoplastic Polyurethanes

TPUs form physical, rather than chemical, crosslinks that can be broken by reheating. Formation of these crosslinks can be sped up by annealing, which improves a variety of properties.

Polyurethanes exhibit an incredible range of chemistries and structures that may be unmatched in the world of polymers. While all polyurethanes are fundamentally the product of a reaction between an isocyanate and an alcohol, the exact chemistry of these ingredients can be varied significantly to create a wide range of properties. In addition, altering the ratio of what are referred to as the hard and soft blocks within the structure produces different property balances that are typically indicated by the property of surface hardness, beginning as low as 60 on the Shore A scale and extending up to 75 on the Shore D scale.

Polyurethanes can be chemically crosslinked to form thermosets or they can be thermoplastic. And while these materials are generally considered to be elastomers, rigid urethanes also exist and the mechanical properties of these materials can be further modified with the addition of reinforcing fibers.

Polyurethane chemistry is the key to the way the performance of these materials can be improved when parts molded from thermoplastic urethane (TPU) are annealed. The properties of as-molded TPU parts are not fully developed, and the maturation process can take weeks if the parts are stored at room temperature. During this maturation process, mechanical and thermal performance improves due to the formation of physical crosslinks. These do not have the permanence of chemical crosslinks and they can be broken by high temperatures so that the material will still melt. But physical crosslinks do enhance performance across a significant temperature range. The rate of formation of physical crosslinks is increased through annealing. And while the literature on annealing often suggests that the process simply reduces the time required to achieve an ideal structure, the reality is that annealing under the right conditions can actually drive performance to a greater level than can be achieved at room temperature regardless of how long you wait.

Since even the softest TPU’s do not soften until the temperature reaches about 150 C/302 F, the general guidelines for annealing these materials consist of a recommended temperature of 110 C/230 F for a period of 16 to 24 hr. However, with harder grades, where the onset of melting may not occur until 200 C/392 F, it is possible to employ higher temperatures.

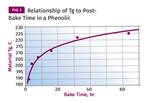

As we have already established, annealing is performed on different classes of materials for different reasons. For amorphous resins, it is an established technique for reducing molded-in stress. In semi-crystalline thermoplastics, annealing is performed above the glass-transition temperature (Tg) of the polymer to create a higher degree of crystallinity. In thermosets the purpose is to increase the degree of crosslinking, which also increases the Tg of the material (see last month’s column).

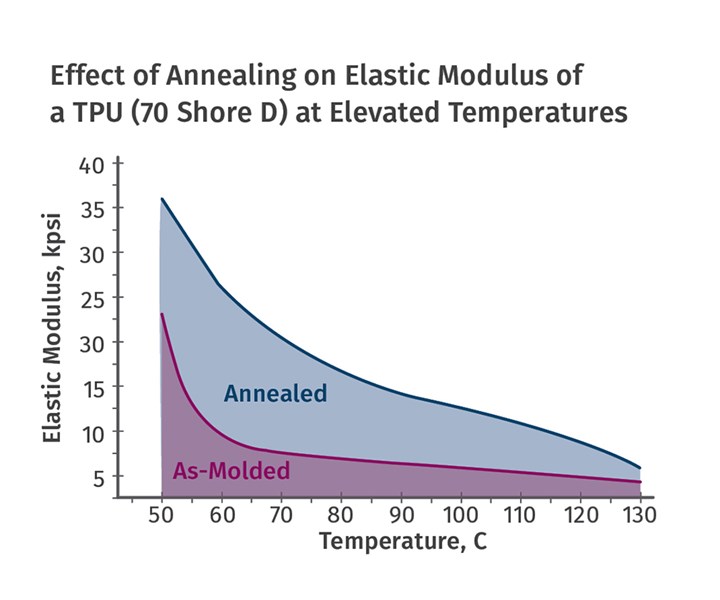

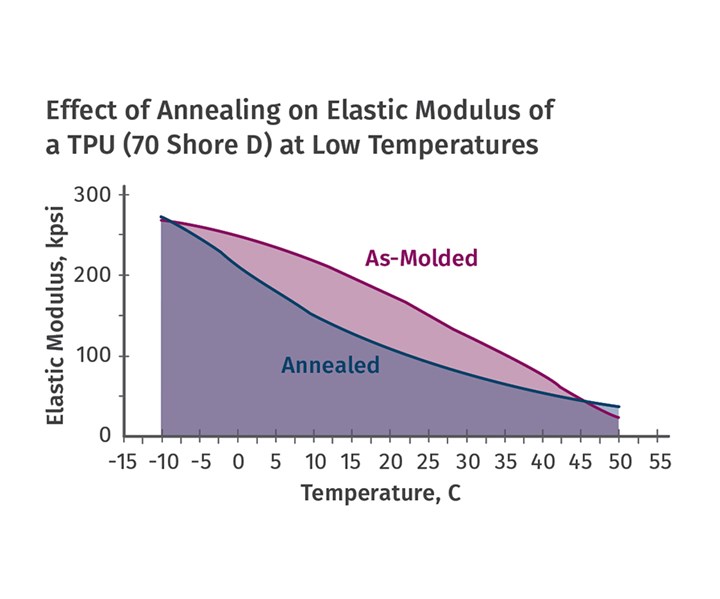

However, in TPU materials, the process enhances performance at both ends of the temperature spectrum. Annealing has been shown to improve properties at elevated temperatures, but it also enhances low-temperature performance by reducing the Tg of the polymer. The useful temperature range of an elastomer is defined by these two benchmarks. Below the Tg, elastomers become hard and brittle and no longer have the desired flexibility and damping. At the high-temperature end of the spectrum, the crystal structure that makes up the hard segments begins to melt and load-bearing properties decline. Annealing has been shown to improve elevated-temperature performance while reducing the Tg.

Figure 1 shows a comparison of the elastic modulus (E′) of a TPU with a nominal Shore hardness of 70D before and after annealing. The annealing process raised the modulus of the material above room temperature. This improvement solved a problem with deformation that was occurring in molded parts during an assembly process conducted at elevated temperatures. At the same time, the annealing process decreased the room-temperature stiffness of the material, giving it a better “feel” at these conditions and maintaining that softer tactile response down to subambient conditions. This is shown in Figure 2.

FIG 1 Annealing raised the modulus of this TPU above room temperature, which solved a deformation problem that occurred during an assembly process conducted at elevated temperature.

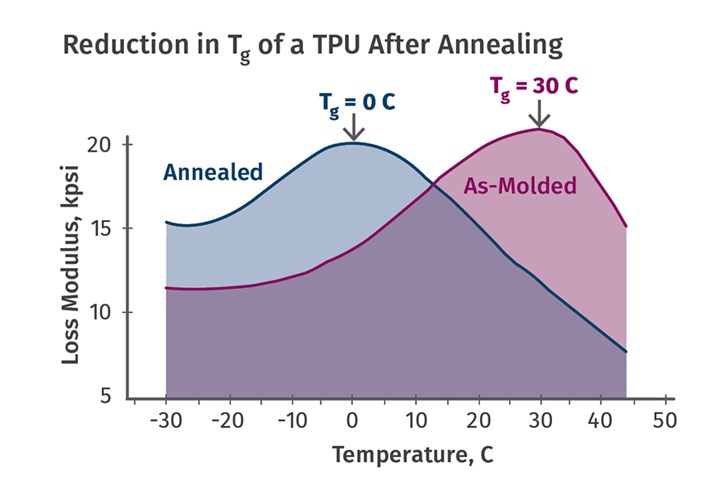

FIG 1 Annealing raised the modulus of this TPU above room temperature, which solved a deformation problem that occurred during an assembly process conducted at elevated temperature.A property known as the viscous modulus or loss modulus (E″) is used to highlight the glass-transition region and identify the Tg. By convention the Tg is taken as the peak temperature of the loss modulus. Figure 3 shows the comparison of this property for the as-molded and annealed material. In the as-molded material the Tg is above room temperature, but in the annealed product it is well below RT.

FIG 2 Annealing also decreased the room-temperature stiffness of this TPU, giving it a better “feel” at ambient and subambient conditions.

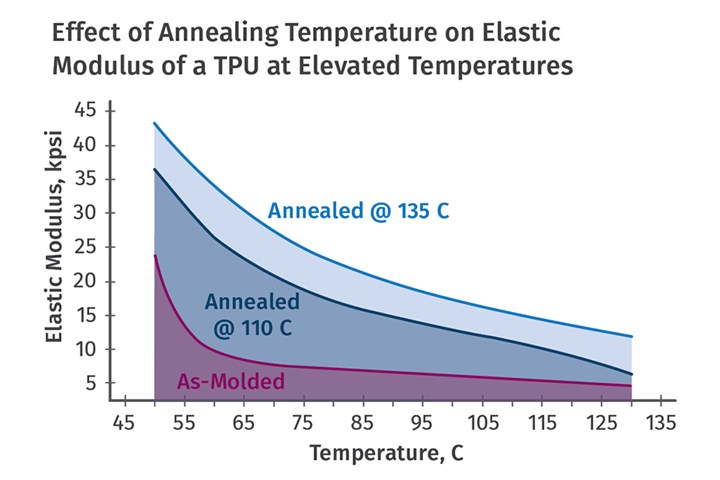

This annealing routine consisted of 16 hr at 110 C/230 F. When the improvements in performance at both ends of the temperature spectrum were noted, we explored the possibility of obtaining further improvement by increasing the annealing temperature. Raising the annealing temperature to 135 C/275 F produced an additional improvement in elevated temperature performance as shown in the elastic modulus comparison provided in Figure 4.

FIG 3 Annealing lowers the glass-transition temperature (Tg) of a TPU, defined by convention as the peak temperature of the loss modulus.

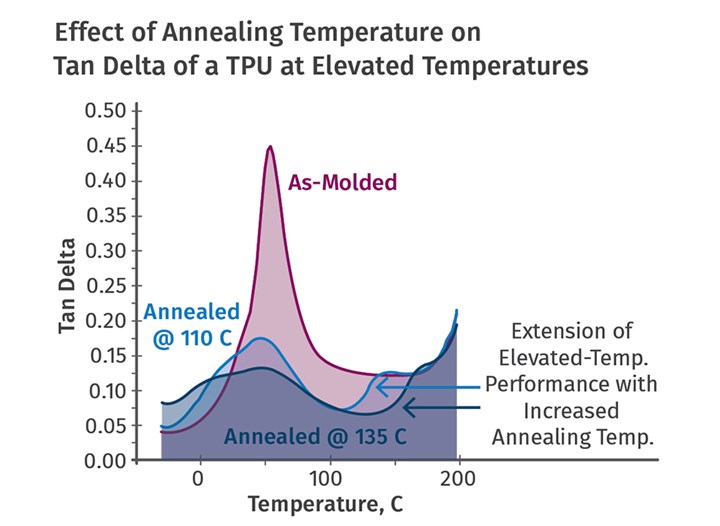

Another property that helps to illustrate the benefits of annealing is tan delta. This property represents the balance between the elastic and viscous response of a material to applied stress. Higher tan delta values are associated with improved damping, while lower tan delta values equate to improved creep and fatigue resistance.

FIG 4 Raising the annealing temperature produced an additional improvement in elastic modulus at elevated temperatures.

Figure 5 shows the effect of annealing on this property. Note that annealing at 110 C/230 F reduces the tan delta profile between room temperature and 140 C/284 F. Above this temperature the tan delta values for the as-molded and annealed material become essentially equivalent. This shows the relationship between the annealing conditions and the temperature range over which performance improvements take place. Note that by increasing the annealing temperature by 25o C/45o F, the performance improvement is extended by essentially the same amount. The high melting point of this grade of TPU makes this higher-temperature annealing routine possible.

FIG 5 Annealing reduces the tan delta profile at elevated temperatures up to 140 C, which corresponds to improved creep and fatigue resistance. Raising the annealing temperature extends the range of this improvement to higher temperatures.

The practical importance of the effects of annealing in TPU are remarkable. In this case the annealing process took a material that was unsuitable for the desired application at both ends of the spectrum and converted it into a product that met all the application requirements. So, when evaluating TPUs for application performance, it is beneficial to remember the strategy of annealing.

In our next and last installment on this topic we will look at a special case of annealing in an amorphous thermoplastic that produces benefits normally associated with post-baking in crosslinked materials.

ABOUT THE AUTHOR: Mike Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe, LLC, is based in Sedona, Ariz. He has more than 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

Hybrid EPDM-TPE Adhesion Compounds for Automotive Industry

Kraiburg’s new compounds targeted to auto sealing and exterior sector applications and toolmakers.

Read MoreEther-Based TPUs for Broad Range of Industry Applications

BASF’s Elastollan 1400 TPU series can be used for applications ranging from railway pads, hoses and profiles to show soles.

Read MorePrintable Thermoset Polyurethane

Chromatic 3D Materials launched ChromaMotive D65, designed for additive manufacturing.

Read MoreTracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreRead Next

Materials Part 5: Annealing Tips for Crosslinked Polymers

As with semi-crystalline thermoplastics, annealing can be used in thermosetting polymers to obtain a level of crosslinking that may not be possible within the molding cycle.

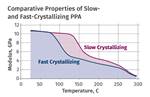

Read MorePart 3 Materials: Annealing Tips for Semicrystalline Polymers

For these polymers, annealing is done to establish a level of crystallinity that cannot be practically obtained within the parameters of a normal molding cycle. Here’s some guidance on setting annealing time and temperature.

Read MoreMaterials: Annealing Tips for Semi-Crystalline Polymers: Part 4

You can forgo the elevated mold temperatures normally recommended for high-performance semi-crystalline materials. But it’s risky and likely to yield parts that under-perform expectations … assuming that they emerge from the annealing process looking anything like the drawing.

Read More