Blow Molding

Blow Molding: Compact, Integrated Blowing & Labeling System for PET Bottles

Integrating PET bottle blowing and labeling saves floorspace and prevents bottle damage in conveying.

Read MoreNovel Dual-Wheel Blow Molder Allows Quick Product Changes

Two wheels, one extruder, two sets of molds: all you need to change products without a mold change.

Read MoreBlow Molding: Faster, Super-Compact PET Blow-Fill-Cap System for Still Water

Sidel’s new Super Combi Compact is 30% faster and occupies 30% less floorspace.

Read MoreNovel PET Water Bottle Pushes ‘Eco-Friendly’ Boundaries

Sidel’s AYA offers super-light weight, 100% rPET content, and reduction of secondary and tertiary packaging materials.

Read MoreInjection Molding: Lubricant Coating Keeps PET Preforms Scratch-Free

Prevent scratching of PET preforms during bulk packaging and handling with a new system for spraying a lubricant coating on the preforms.

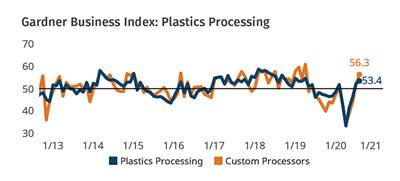

Read MorePlastics Processors Report Quickening Expansion

Expansion among both captive and custom processors is driven by expanding orders, production, and employment.

Read MoreOne-Step Method for Blow Molding Composites

Lanxess forms and bonds Tepex composite sheet to a blow molded parison in the mold.

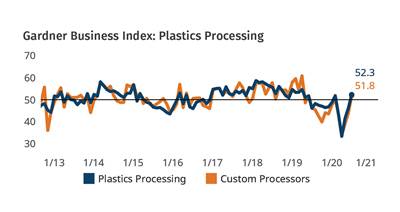

Read MorePlastics Processing Expands in July

With an Index reading of 52.3, processors report first monthly expansion since the coronavirus disruption.

Read MoreLighter Weight & PCR Content in Multi-Trip PET Bottles

Refillable PET bottles are a significant factor in Mexico and parts of Latin America, as well as in Germany. This development combines 15% lightweighting with 35% recycle content.

Read MoreBlow Molding: Conveyor Designed for Integration with Blow Molding Machines

Compact unit can handle melt purges, separates tails and tips, and repairs quickly and easily.

Read More