Blow Molding

Making a Part for the First Time? Here’s How to Get Going

First time parison programming for a new part can be lengthy and tedious. Here's some advice on making the process a bit easier

Read MoreBonanza of Hot Runners & Controls Introduced at K 2010 Show

At the world’s largest plastics show in Dusseldorf last fall, hot-runner and controller manufacturers introduced a flood of new developments in speed, size, accuracy, and reliability.

Read MoreFoamed PET Bottles for Beer

Now the foam isn’t just on top of the beer, it’s all around it.

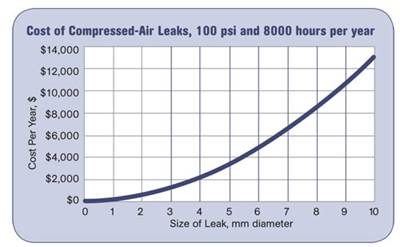

Read MoreEnergy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

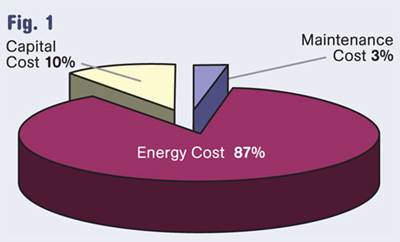

Read MoreCompressed Air Isn’t Free!

Compressed air is a convenient and often essential utility, but it is very expensive to produce, and most of the energy used to compress air is turned into heat and then lost to the system and environment.

Read MoreBLOW MOLDING: Electric Machines Starting to Purr

Growing use of electric drives in blow molding machinery gathered steam at the K 2010 show, as suppliers rolled out new all-electric and hybrid models for extrusion blow, injection-blow, and stretch-blow production.

Read MoreOn-Site: This Currier Delivers

“We love to tell our story.” That’s one way Mike Cartner, CFO of Currier Plastics, defines what separates this family-owned custom processor from its competitors.

Read MoreK 2010 Preview, Blow Molding New Machines Promise More Output with Less ‘Juice’

Higher throughputs and greater energy efficiency will be two big themes in blow molding at next month’s K 2010 show.

Read MoreBlow Molding: Increase Your Machine Uptime…And Profit

In the early days of industrial blow molding, the processor had quite a few obstacles to overcome.

Read More