Engineering Resins

Automotive Composites Get A Boost From New Predictive Engineering Tools

Government-industry-academic consortium develops engineering software to predict mechanical properties of long-fiber thermoplastic composites.

Read MoreAbrasion Resistant Alloys for Injection Molding

RTP's alloys are comparable to UHMWPE in abrasion resistance but can be injection molded.

Read MoreLyondellBasell to Acquire A.Schulman

Acquisition to create an industry-leading compounding business.

Read MoreSABIC Weighs In On Additive Manufacturing Materials

Overarching trend in plastics additive manufacturing: transition from a history of prototyping to a future of end-use part production.

Read MoreMolding with Nylon: Tips & Tricks

Remember to consider shrinkage, gassing, and moisture when molding this versatile, but at times vexing, engineering plastic.

Read MoreIBM Tackles Chemical Recycling of Plastics From Post-Consumer PC (Think CDs) to a Thermoset

Jeannette Garcia, polymer chemist at IBM Research, details her research into chemical recycling of plastics for monomer recovery.

Read MoreEngineering Resins Maker Focuses on 3D Printing Materials

SABIC develops arsenal of specialty products based on its engineering resins for a new range of processes.

Read MoreNew Engineering Materials for Challenging Automotive Applications

Nylons, PPA, and PPS for high heat and chemical resistance and/or high strength with light weight.

Read MoreMaterials: New Nylon & PET Electrical Compounds

New Rynite and Zytel grades for automotive electrical parts and household appliances.

Read MoreLong Fiber PP Compounds Drive Innovation in Automotive

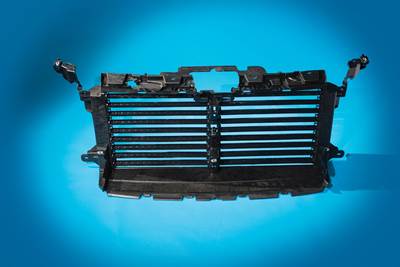

Long fiber thermoplastic polypropylene ( LFT PP) is now widely used in automotive front-end carriers, instrument-panel carriers, door panels, consoles, pedals, under-body shields and more.

Read More