Extrusion

Shhh ... Can You Hear the New Extruder Motors?

Silent, space-saving, energy-efficient, and high-torque, a new generation of ring-shaped motors is gaining a foothold in extrusion. A couple of hundred are already in use. Though most machine builders are reacting cautiously, adventurous processors are using them happily.

Read MoreChasing Nanocomposites

Nano-sized particles have mega-potential in plastics because just a pinch does so much more than heavy loadings of other additives. Three recent conferences presented almost 200 papers on the feverish pace of ‘nano’ R&D on boosting plastics’ mechanical and barrier properties, flame retardancy, and electrical conductivity.

Read MoreFrom Paper-Mill Sludge to Plastic Decking

Kadant Composites’ self-appointed mission for the past eight years has been to find commercial uses for paper sludge, a soggy mix of short cellulose fibers, calcium carbonate, and clay that is the copious byproduct of paper recycling.

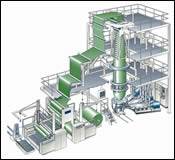

Read MoreK 2004 News Preview: Extrusion

At K 2004, at least a half-dozen European machine builders will show new direct-drive extruders running gearless—or nearly gearless—drives with substantially higher rpm and output rates than conventional extruders of the same size.

Read MoreExtrusion Coaters: Stop That Edge Weave

In extrusion coating, edge stability depends on uniform melt temperature.

Read MoreBeyond Decking: Wood Composites Branch Out

Extruded decking still drives the embryonic wood-filled plastics market. But injection and compression molded wood composites are coming on strong, and extruded profiles are moving toward more complex millwork shapes.

Read MorePPS Role Shapes Up in Thermoforming

Thermoformers may find new opportunities in higher-performance applications with the arrival of thin-gauge PPS sheet from Penn Fibre Plastics (PFP). Highly crystalline PPS has until now resisted extrusion at less than 0.25-in. thickness due to its poor melt strength and the resulting sheet’s tendency toward brittleness.

Read MoreBelt Polishing of Clear PP Film Proves Itself in Production

An unusual cast-film process that drops a melt curtain of polypropylene between a flexible steel polishing belt and a chill roll has now proven successful in high-volume commercial production.

Read MoreRecycled PET/PE Alloys Show Promise In Monofilament, Pallets, Pipe

Alloys of polyethylene and recycled PET were the highlight of the annual SPE Global Plastics Environmental Conference (GPEC) in Detroit in February.

Read MoreThey've Been Working on the Railroad

Composite RR ties could finally be on their way to becoming the next big thing in plastic lumber. They are attracting interest from makers of marine pilings, another category of structural wood replacements.

Read More