Feeding & Blending

10 Things to Know When Specifying Vacuum Conveying Systems for Powders

The priority is to maximize movement of powders while minimizing dust exposure.

Read MoreUnderstanding Low-Rate Feeding for Continuous and Batch Processes

Molders and extruders that need to feed tiny amounts of material to their process require precision in both the material being fed and the equipment doing the dosing. When a shot size consists of three pellets, there is no margin for error.

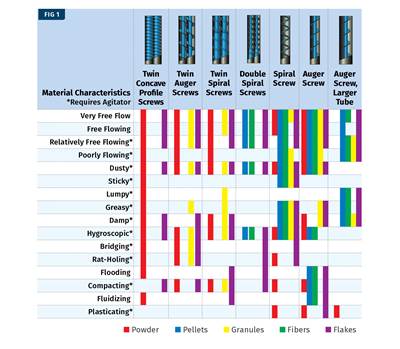

Read MoreOptimize Feeding to Get More Money in Twin-Screw Compounding

Follow these practical examples to improve the feeding efficiency and productivity of your process.

Read MoreAugmented Auxiliaries At K 2016

Incremental improvements to existing technologies combined with altogether new advances at the giant show.

Read MoreAuxiliary Equipment Suppliers Take Partners to Boost Extrusion Offerings

Maguire and Moretto acquire extrusion equipment and controls.

Read MoreHow to Troubleshoot Your Feeder to Achieve Optimal Performance

Even the tiniest improvements in compounding feeder accuracy can improve profits. Here’s how to keep your feeding system in the pink.

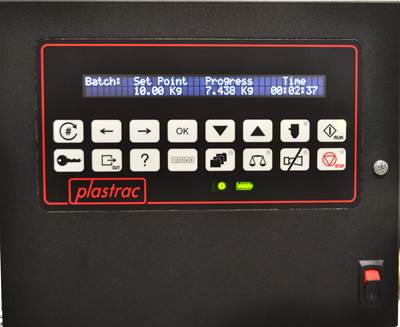

Read MoreAUXILIARY EQUIPMENT: Batch Software for Offline Mixing with Blenders

Ensures that the system blends at the fastest rate possible for any given materials.

Read MoreAUXILIARY EQUIPMENT: New Controls for Conveying, Mobile Drying

New dense-phase conveying system among the new products Conair to display at K.

Read MoreWittmann’s 40th Anniversary Gala Unveils New Products

New machinery, robots, and auxiliaries demonstrate continued momentum of technical development—and preview some K 2016 exhibits.

Read MoreAdd Dirt to Your Resin?

No, it’s not recommended, but some people do it anyway. Inadvertently, through carelessness or lack of training.

Read More