Film Extrusion

Shredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

Read MoreFive Steps Toward a Flawless Flat Film Start-Up

A poor line start-up benefits no one … except your competitors. Follow these five steps to get your film line fired up seamlessly.

Read MoreAre You a ‘World-Class’ Processor?

Participate in Plastics Technology’s industry-wide benchmarking survey and you might find out.

Read MorePutting the ‘Flexible’ in Flexible Film Processing

This blown film processor is no stranger to change when it comes to finding new markets with novel products. Its latest: barrier films.

Read MoreProcessors Align to Offer FFS Solutions

A maker of forming films for packaging and a maker of lidstock films join forces.

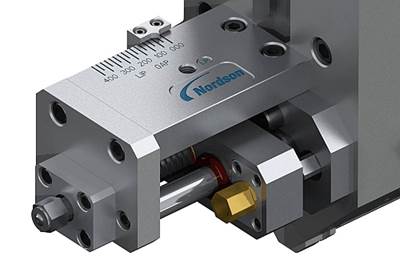

Read More‘Breakthrough’ Tech Allows for Fast Sheet-Thickness Changes

New system uses a single-point adjustment to change the lip gap and modify the lip land length at the same time.

Read MoreEntek Running World’s Largest Line for Lead-Acid Battery Separators

Machine-building sister company furnished the twin-screw extruder and most other line components.

Read MoreEXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

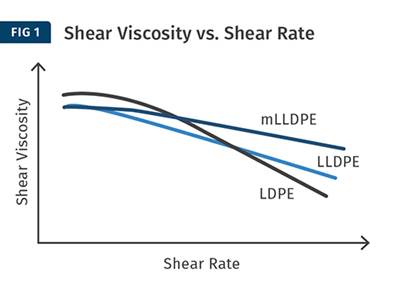

Read MoreCoextruding Blown Film Needs Deeper Understanding of Resin Rheology & Die Design

More film processors are investing in lines with nine or more layers. With more resin possibilities and combinations coming into play, it’s important to learn more about material rheology and compatibility, as well as die design.

Read More