Heating & Cooling

Paratherm Moves to New Headquarters

Less than 2 miles from the former location, with more lab and conference space.

Read MoreMedical & Auto Molder Explores New Tech for Tooling & Cooling

Additive manufacturing and liquid-CO2 spot cooling are the firm’s newest tools for boosting productivity and quality.

Read MoreIntegrated Process Cooling Boosts Output, Cuts Costs

Closed-loop system helps an extrusion processor maintain quality of reusable straws and other products.

Read MoreINJECTION MOLDING: Improving Barrel-Temperature Measurement and Control

Proper thermocouple placement and contact area are crucial, as is wire maintenance. But remember that barrel temperature and melt temperature are not the same

Read MoreINJECTION MOLDING: Get Control Over Barrel Zone Temperature Override

Poor temperature control results in an erratic melt stream and process. Here are some tips on how to get things under control.

Read MoreGet Back to Basics On Water-Cooling Equipment

Neglecting your plant water systems can result in inefficiencies and downtime. Follow these tips when you get new equipment on stream or to maintain what you’re already running.

Read MoreThermal Care Breaks Ground on New Building

Relocation to new facility is planned for March 2016.

Read More'Talking’ Machines Pave the Way for Processing Plants of Tomorrow

At the convergence of smarter equipment, open communication protocols, and more powerful networks, a new shop floor emerges where groups of intelligent machines work seamlessly as integrated systems.

Read MoreAir-Ring Upgrades Get Film Processor Quickly Up to Spec

PolyExpert’s trials lead to installation of three new air rings and one digital IBC control to speed changeovers and reduce scrap.

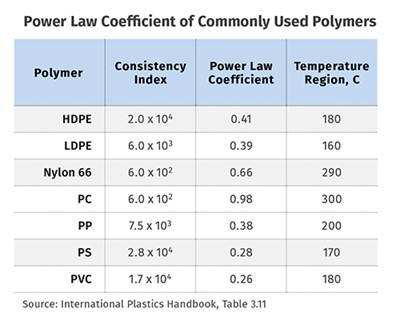

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

Read More