Injection Molding

Injection Molding: All-Electric Machine Line Expands

Engel has added a 130-ton press to its all-electric line of e-mac machines, which now ranges from 50 to 280 tons.

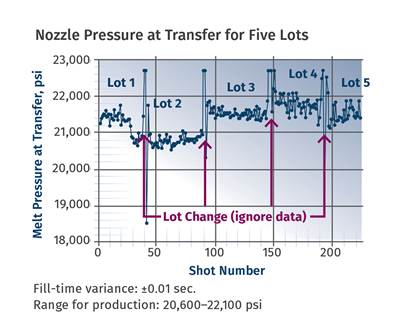

Read MoreHow to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

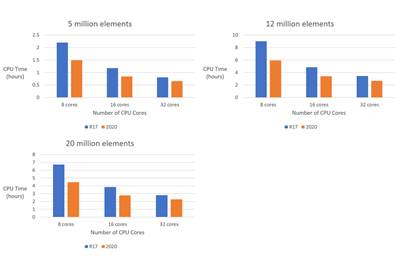

Read MoreInjection Molding: Updated Mold-Filling Analysis Is 30% Faster

Coretech System of Taiwan says its new Moldex3D 2020 solver averages 30% faster calculations than the preceding R17 version with the same computing hardware.

Read MoreInjection Molding: Lubricant Coating Keeps PET Preforms Scratch-Free

Prevent scratching of PET preforms during bulk packaging and handling with a new system for spraying a lubricant coating on the preforms.

Read MoreArburg Announces Summer Dates for Technology Days 2021

Cancelled in 2020 due to COVID-19, Arburg says its annual Technology Days event at its Lossburg, Germany headquarters will go forward in 2021, moving from the Spring to June 9-12.

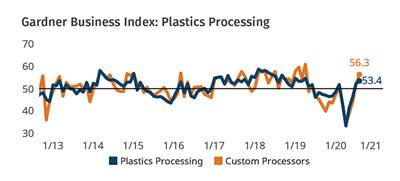

Read MorePlastics Processors Report Quickening Expansion

Expansion among both captive and custom processors is driven by expanding orders, production, and employment.

Read MoreInjection Molding: Hybrid Line Targeting Packaging Adds Lower Tonnage

Engel has added a 280-ton machine to its e-speed series of injection molding machines, targeting makers of thin-walled containers, buckets and matching lids.

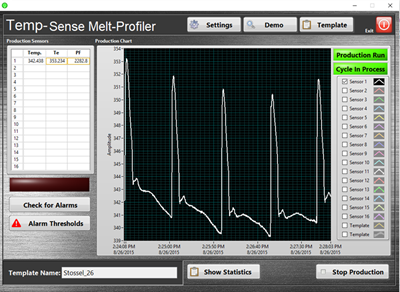

Read MoreMelt-Temperature Measurement Shows New Potential for Monitoring & Control

Unique melt-measurement system provides new types of data for quality and process control. A new version is coming soon.

WatchA Window of Opportunity Opens to One Million Parts a Day

Injection molder and moldmaker Lawrence Industries was founded on the promise of plastics as a replacement for metal in window hardware—a market it now dominates.

Read MoreInjection Molding: PET Preform Molding Machine Switches to Side Entry

Netstal’s new PET-LINE has changed from top entry and post-mold cooling above the clamping unit to side entry and cooling alongside the press, offering compatibility to lateral removal tools and after-cooling stations.

Read More