Molds & Tooling

New Webinar: How to Use Simulation to Reduce Material and Part Cost

Register for this free webinar on reducing downstream risk through injection molding simulation software. (Sponsored Content)

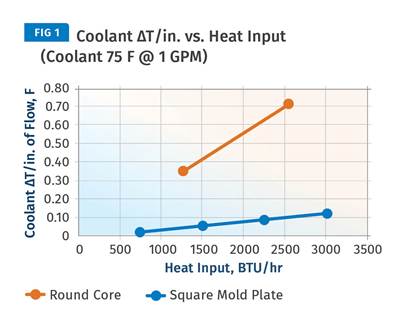

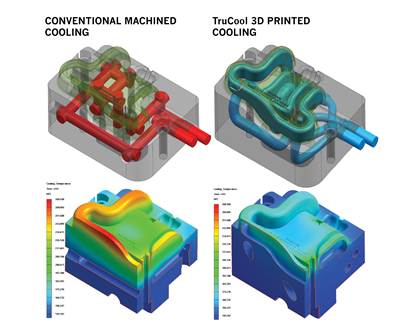

Read MoreAn Engineering Approach to Mold-Cooling Circuit Design

The Energy Density vs. ΔT/in. relationship is an important step forward in pursuit of a science-based approach to cooling-circuit design. Here’s why.

Read MoreTooling: Clamp Pressure & Cavity Land Area, Part 2

What you need to know to prevent flashing and mold damage.

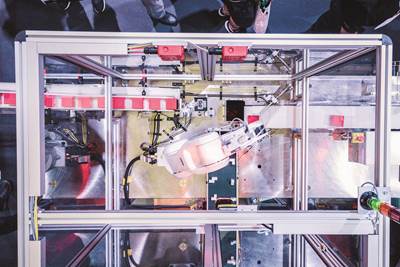

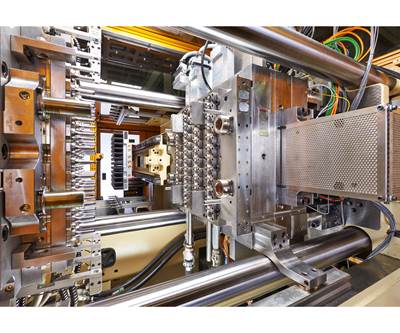

Read MoreNew System Runs Two Molds in One Press Simultaneously

Shuttle-mold system is one of several eye-popping innovations that Canon Virginia brought to NPE2018.

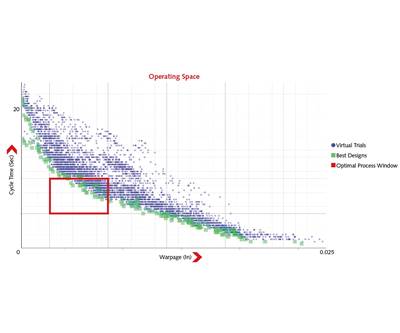

Read MoreAutomate Injection Molding Simulation With Autonomous Optimization

Simulation not only predicts how a mold will fill, but also provides guidance to make it fill better. The new technology of Autonomous Optimization automatically performs hundreds or thousands of simulations, testing multiple variables—gating, venting and cooling, for example—and learning which combinations help achieve objectives for injection pressure, cycle time, warpage, etc.

Read MoreAutomotive Tooling Keeps Foot on the Accelerator

The tooling industry looks to remain strong throughout 2018 as key indicators—sentiment, back logs and utilization—all register positive.

Read MoreNPE2018 New Technology Focus: Mold Components, Supplies, Maintenance

Advances include new approaches to tool maintenance and monitoring.

Read MoreBarrier PET Containers Highlighted at Husky Booth

Husky’s Multi-Layer Experience Center will be a highlight of its booth.

Read MoreNew Mold Monitoring System Promises Fast Processing Speeds and High Resolution

The full-color, high-resolution digital image processing technology serves to protect complex, expensive injection molds running sub 2-second cycles.

Read MoreMilacron Is ‘Going Big’ at NPE2018

Milacron is emphasizing large-tonnage injection presses, enhanced customer service to maximize their uptime, and speed—both speedy delivery of parts and suppies, and products that speed up production for their customers.

Read More