Molds & Tooling

Determining Vent Depths in Injection Molding

Experiments reveal the relationship between vent depths and part thickness, allowing molders and moldmakers to more precisely determine vent dimensions.

Read MoreTooling: New Standard Mold Components

Stack-mold actuators and mold monitors stood out from the crowd of new mold components at Fakuma 2017 from Hasco, Meusburger, Haidlmair, and Progressive Components.

Read MoreInjection Molding: News in Sensors, Quality Monitoring, And Quick Mold Change

Priamus debuts simple on-machine quality monitor plus new styles of cavity sensors and a quick connect for cavity sensors in quick mold changes.

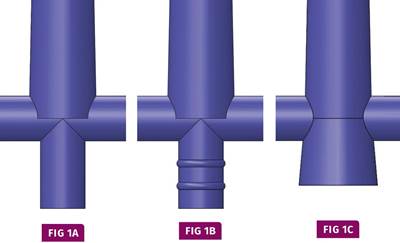

Read MoreHow Sprue Pullers Help Prevent Molding Issues: Part 2

A vital secondary function of sprue pullers is to act as a cold well to trap solidified material left in the machine-nozzle tip.

Read MoreInjection Molding: New Mold Trial—Will It Run 24/7?

Use this nine-step process to make sure you’ll be making good parts after a successful trial. But even then, be prepared for some hiccups.

Read MoreNews in Hot Runners & Tooling At Fakuma 2017 Show

Highlights included some unusual solutions to common problems, slim nozzles for close spacing, and controls with lots of zones, as well as a handful of new cost- and space-saving standard mold components

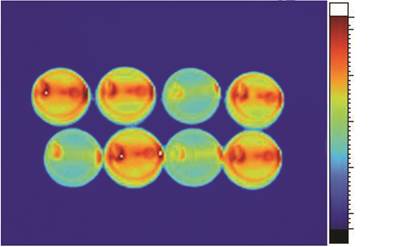

Read MoreAn Inside Look at Turbulent Flow

Years of talk about observing and studying coolant flow in a clear simulated cooling channel finally becomes a reality. Here’s how it all came together, and what it all means.

WatchTooling: New Hot-Runner & Mold Components Shown at Fakuma

New standard products for hot runners and mold bases.

Read MoreMeusburger Adds Hot Runner Nozzles

Meusburger now offers hot-runner nozzles from its PSG subsidiary.

Read MoreTooling: Know the Basics of Sprue-Puller Design

Sprue-puller designs are quite varied, and there are no firm rules to follow. But here are some important cautions and caveats to keep in mind.

Read More