PET Processing - Extrusion

Are You Ready to Take on the World?

Plastics Technology’s exclusive benchmarking study reveals the tactics of processors who just might be in that class.

Read MorePTi to Expand Headquarters

The sheet extrusion machinery supplier will invest $10 million in an expansion that will nearly double manufacturing space and capacity at its Aurora, Ill. headquarters.

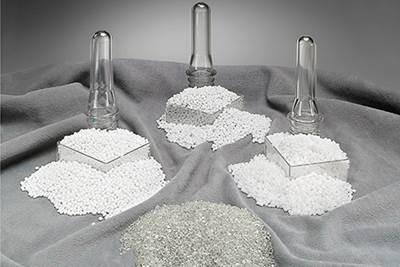

Read MoreWhy & When Should You Re-Crystallize PET Scrap?

Whether you’re blow molding PET bottles or extruding APET sheet, you’ll produce amorphous scrap in the process. How you handle it will impact your production costs. Re-crystallizing it will help.

Read MoreDavis-Standard Buys Gloucester Engineering

Acquisition will expand Davis' blown film and aftermarket business worldwide.

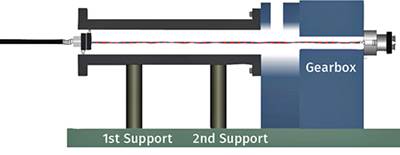

Read MoreKeep Extruder Barrels Aligned…And Production on Target

A misaligned barrel causes a lot of trouble. Laser alignment is being used now to keep things on the straight and narrow.

Read MoreHow to Keep Moisture Away From Your APET Sheet Line

Moisture in PET will result in degradation that will foul up sheet and thermoformed products. Keep it at bay by following these tips when drying APET virgin and flake material.

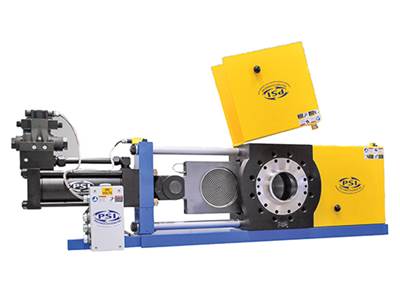

Read MoreEXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

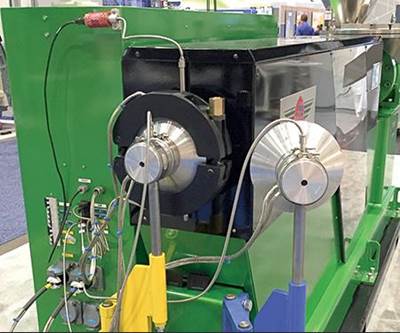

Read MoreKeep Your Screen Changer In the Flow

The screen changer plays an essential role in generating quality extrudate. Here’s what you need to know to keep it functioning properly.

Read MoreAre You a ‘World-Class’ Processor?

Participate in Plastics Technology’s industry-wide benchmarking survey and you might find out.

Read MoreEXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

Read More