PET Processing - Extrusion

Now You Can Measure Pellet Moisture In the Hopper, in Real Time

Take the guesswork out of drying with new technology.

Read More'Dryer-less' PET Sheet System

Processing Technologies International (PTi), recently took the wraps off its “dryer-less” twin-screw PET sheet extrusion system at its headquarters in Aurora, Ill.

Read MoreWhy—and How—to Baseline Your Extruder

If you don’t baseline your extruder, then how are you going to set realistic expectations for its performance? Here's how to get going.

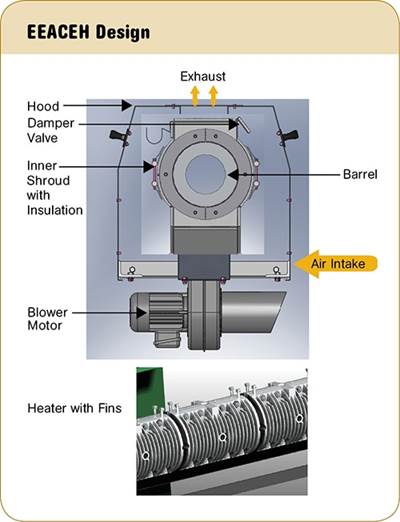

Read MoreNew Barrel Heater/Cooler Saves ‘Juice' to Run an Extruder

New, patent-pending design is said to reduce both radiant and convection heat losses.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

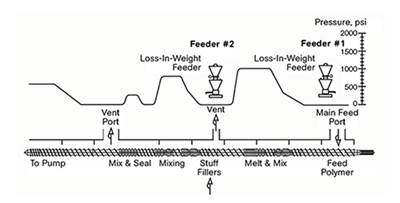

Read MoreLook Before You Leap: When Direct Extrusion Makes Sense

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

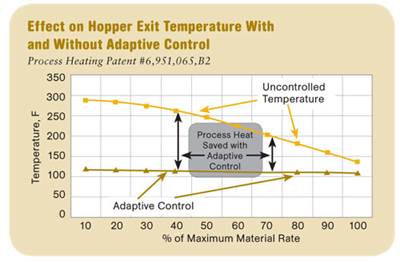

Read MoreDryers Use Less Energy to Dry PET

Novatec Inc., Baltimore (novatec.com), is introducing two patented dryer control technologies intended to cut energy costs for processors of PET.

Read MoreNPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

Read MoreGenpak Pioneers in PET Foam Sheet

Soon after Genpak LLC launched its line of CPET trays for commercial baking in the early 1990s, the firm chose foamed PET as its next R&D target.

Read More