Pipe, Profile & Tubing Extrusion

What to See at NPE 2006: Extrusion

The new factor in extrusion machinery at this NPE is the influx of Asian suppliers.

Read MoreNPE 2006 News Flash

Injection MoldingSimplified Hot Runners Save Time & CostA new lower-cost hot-runner alternative to valve gating is suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation.

Read MoreMoving Die Parts Change Profile Shapes 'On the Fly'

Change one tubing lumen into two, or two lumens into three, or even split one tube into two in a “Y” shape: These are some of the dramatic alterations that can be made “on the fly” with a novel articulated die concept available for license from Specialty Silicone Fabricators, a medical tubing maker in Paso Robles, Calif.

Read More50 Ideas That Changed Plastics

Very few readers of this issue can remember, or even imagine, what it was like when an injection molding machine did not have a screw, but only a smooth-bore plunger.

Read MoreA Plant Designed by Efficiency Experts

Hi-Tech Profiles Inc. in Pawcatuck, Conn., extrudes stock and custom medical and industrial profiles out of engineering resins that cost from $3 up to $35/lb.

Read More'Corrugator Vacuum Forming'

Molding separate hollow parts on a pipe corrugator is a home-grown technique used by a small number of processors. They discovered it offers higher outputs and numerous other advantages over blow molding for making tube-shaped, precision medical, automotive, and appliance parts. But the process has not yet realized what could be its greatest potential in closed-end parts like bottles.

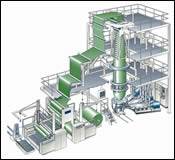

Read MoreK 2004 Extrusion: Outputs Rise, Downstream Units Gain Flexibility

The show was packed with new equipment for pipe and profile, including extruders redesigned for higher outputs and/or lower cost, plus new ways to adjust die and calibrator diameters or switch dies and calibrators more quickly.

Read MoreShhh ... Can You Hear the New Extruder Motors?

Silent, space-saving, energy-efficient, and high-torque, a new generation of ring-shaped motors is gaining a foothold in extrusion. A couple of hundred are already in use. Though most machine builders are reacting cautiously, adventurous processors are using them happily.

Read MoreK 2004 News Preview: Extrusion

At K 2004, at least a half-dozen European machine builders will show new direct-drive extruders running gearless—or nearly gearless—drives with substantially higher rpm and output rates than conventional extruders of the same size.

Read MoreBeyond Decking: Wood Composites Branch Out

Extruded decking still drives the embryonic wood-filled plastics market. But injection and compression molded wood composites are coming on strong, and extruded profiles are moving toward more complex millwork shapes.

Read More