Postprocessing

Blow Molding: New Buffer Integrates Bottle & Cap Molding with Filling Operations

SACMI combines PET bottle blowing, filling, capping, labeling in one machine; coordinates speeds of bottle and cap molding for integrated filling lines; and advances digital cap printing.

Read MoreDecorating/Printing: Versatile Corona Treatment System

Said to improve the surface tension on numerous materials resistant to printing, adhesive, and coating processes.

Read MoreWelding: Ultrasonic Hand-Held System Comes in Multiple Frequencies

Time and energy process control is part of its standard configuration.

Read MoreWelding: Two Compact Linear Actuators for Automotive

A key feature is the distance feedback which will reduce over welds.

Read MoreNew Ionomer Decorative Effects Using Hot Stamping

DuPont collaboration with Kurz Group leads to golden or metallized effects.

Read MoreMolder Gets Hermetic Seal, High Yield with Servo Welder

Supplier of power protection systems avoids redesign of molds by replacing pneumatic ultrasonic welder.

Read MoreWhat Is the Right Plastics Joining Process for You: Part 3—Coolant Manifold Case Study

What is the most appropriate plastics joining solution for a 30% glass-filled nylon coolant manifold?

Read MorePlastipak Wins Award for Direct Object Printing Technology

The patented DOP technology for packaging decoration facilitates rapid label changes & saves on logistical costs associated with physical labels.

Read MoreWhat Is the Right Plastics Joining Process for You: Part 2—Available Technologies

The four primary joining technologies—vibration, clean vibration, infrared, hot-gas/convection—offer different benefits and challenges for different applications.

Read MoreWhat Is the Right Plastics Joining Process for You? Part 1

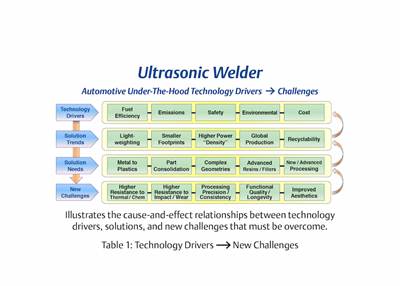

Changing demands, advancing technology and a process-neutral approach to plastics joining for under-the-hood automotive parts.

Read More